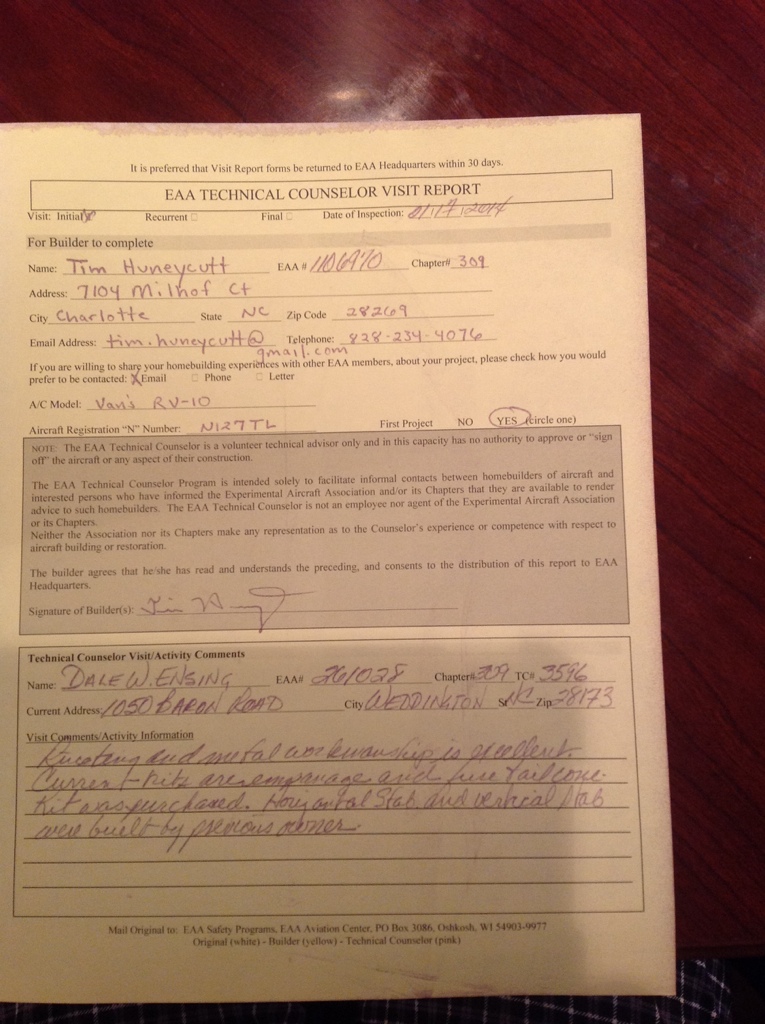

The project got it’s first inspection today when the local EAA Tech Counselor, Dale Ensing, dropped by to take a look at my work. I wanted him to critique my build early on to ensure that I was on the right path and correct any bad habits before getting too far into the project.

As typical, the visit turned into swapping stories and sharing experiences, all of which something can be learned from. People like him make this rewarding project even more fun. He took a good look at the work done thus far by the previous builder and by myself with favorable comments. The main recommendation he had for me was to go ahead and spot prime the outer skins on areas where I had taken of the surface corrosion. I asked him several questions about priming, rivets, other random build techniques and got some great info and tips from him. Best of all, it was an evening spent talking about our passions for aviation!

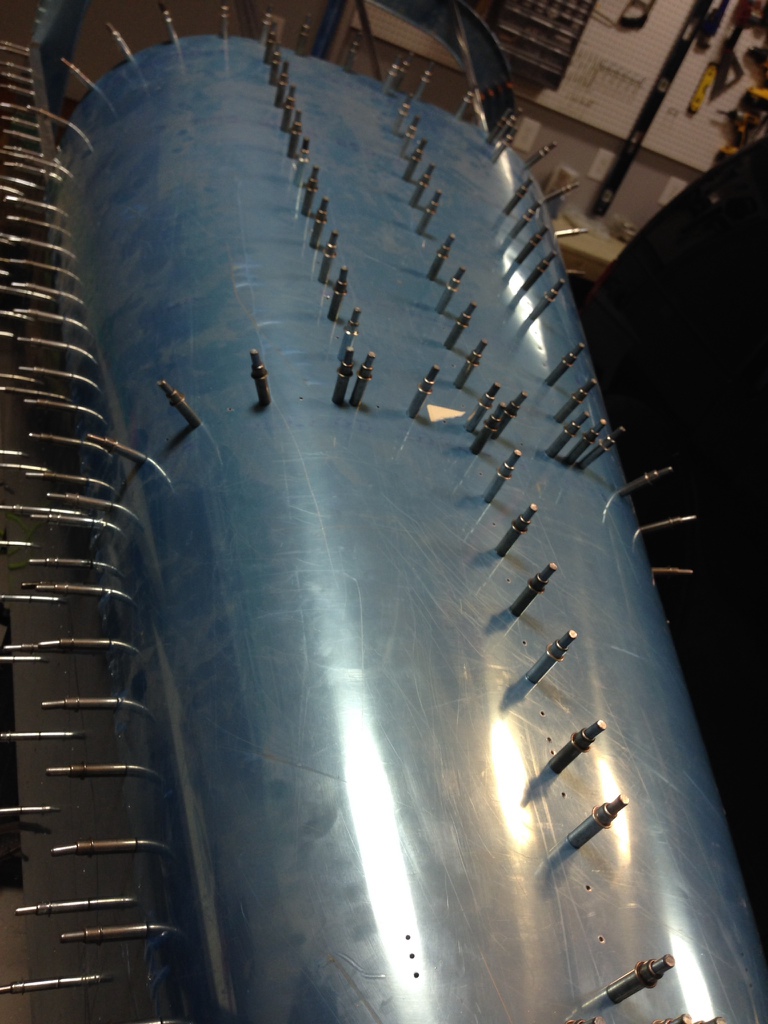

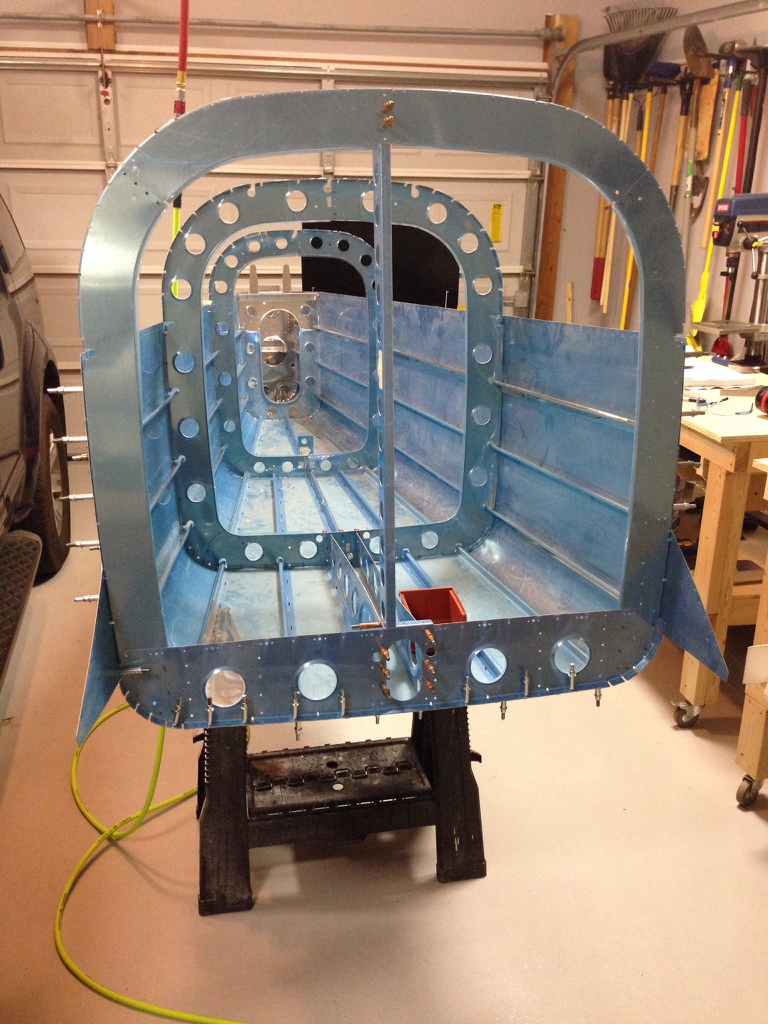

With a boost of confidence and a confirmation of satisfactory work, I’m left with a pile of parts once again after disassembling the tail cone. I began stripping the blue film off pieces and will work now on deburring and dimpling. That will all have to wait at least a week, however, as I’m headed up to Greensboro for a week of flying and hopefully my commercial rating!