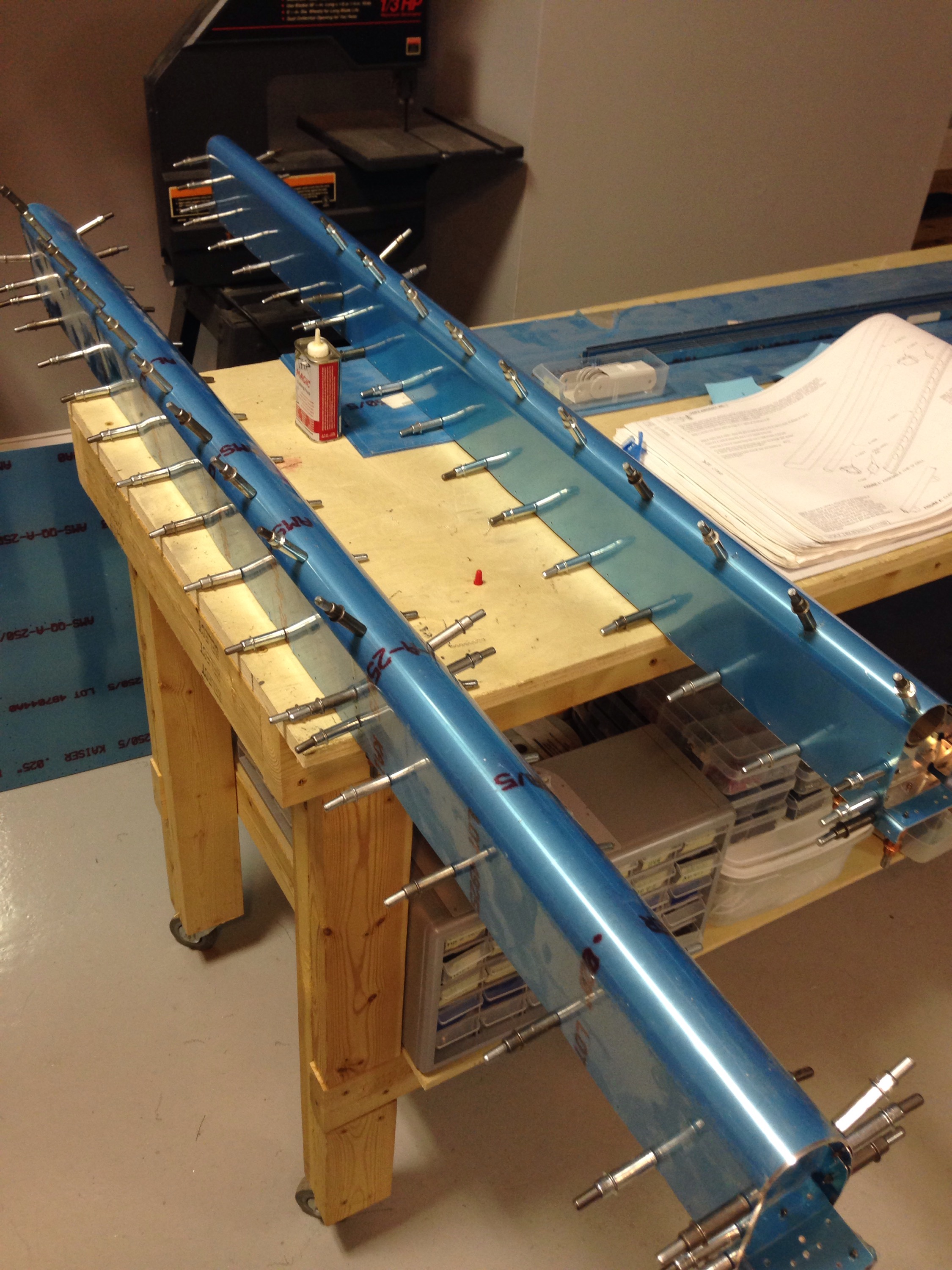

Ailerons are the next project on the wings and I was able to pull all the parts down from the racks while putting away the fuselage. As with the elevators and rudder, it’s a pretty straight forward process. I did have a personal problem of keeping the parts labeled correctly. When I dissassemble, I typically use sharpie marker to label the parts. Problem is when you clean them prior to priming, the sharpie comes off. You can tell your self that you’ll remember or set them in order, but something always happens. I’ll have a plan before attacking the flaps.

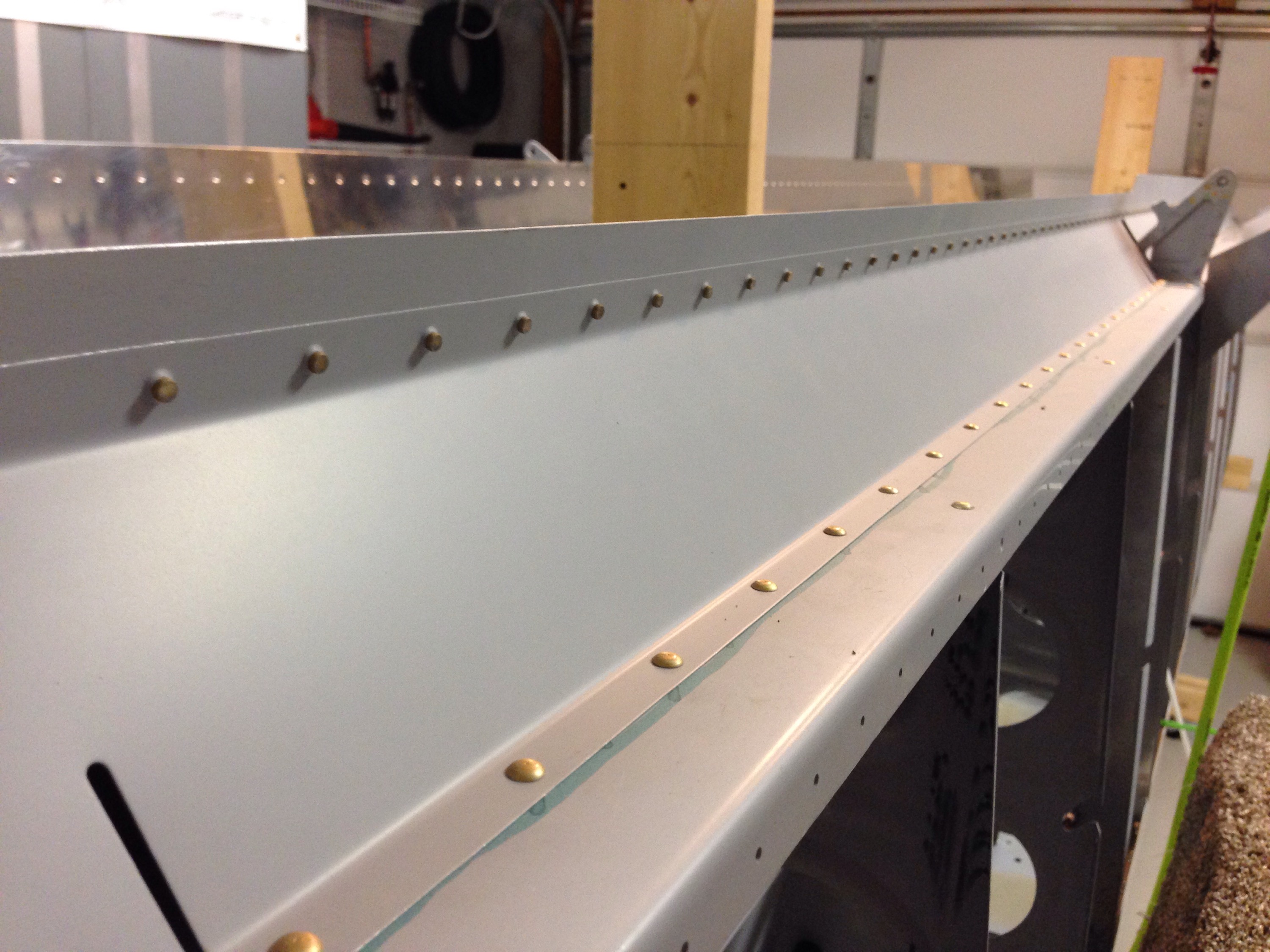

It was a tight fit to buck the bottom skin onto the spar, so the Mrs. came out to insert rivets while I kept my hand burried in the skins. As with the elevators, I elected to not proseal the trailing edges. Withpatience and a good balanced approach, you can get great results back riveting the trailing edge right away and without all the mess.

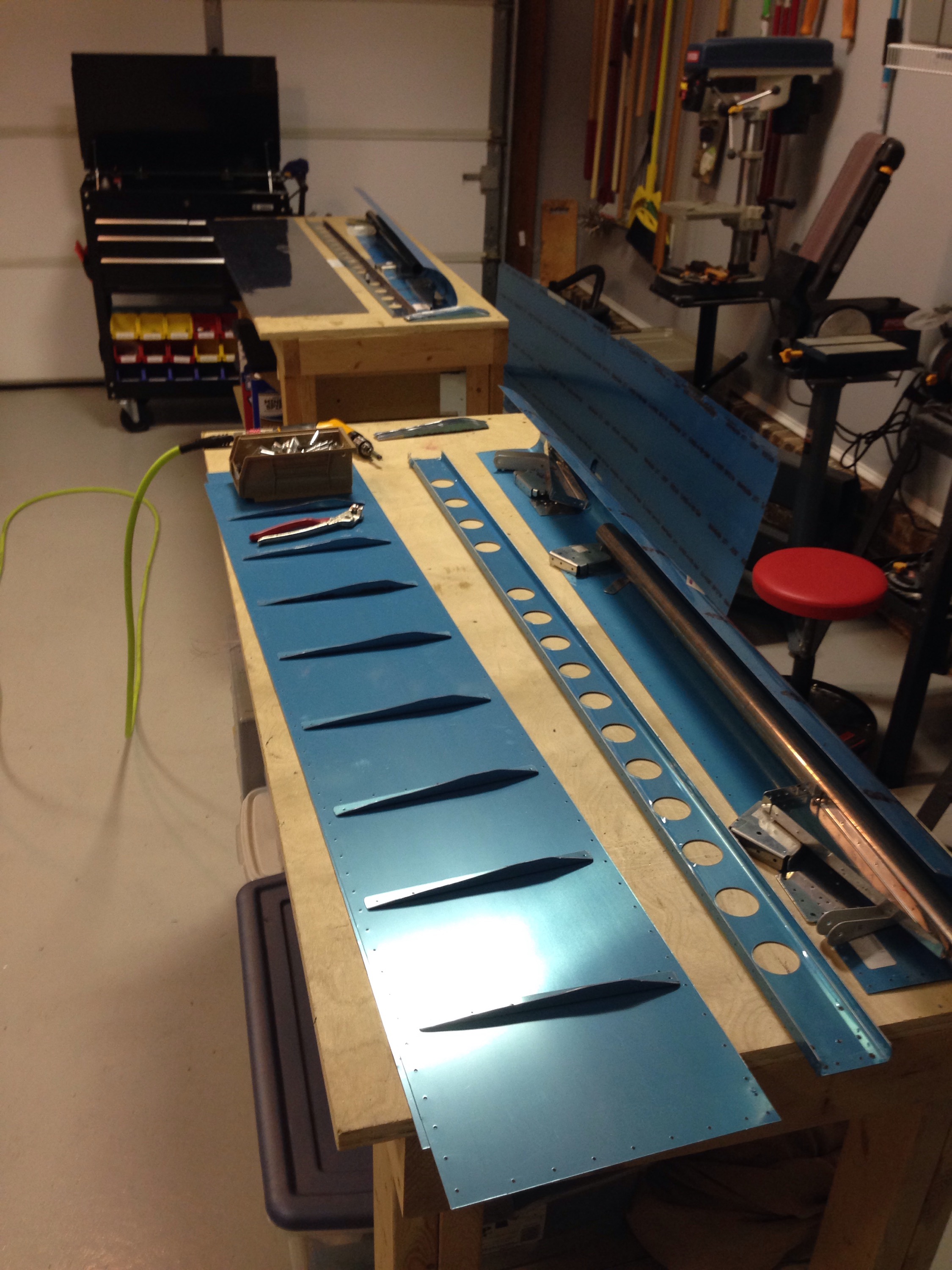

I went ahead and bolted both sides onto the wings once complete. They fit well and add a lot of surface area to the wings, which makes you feel like progress is being made! I’ll tackle the controls before riveting on the bottom wing skins. Flaps are up next.