While having some down time at home that I can’t do much productive anything with, I decided to research quite a few things while lying in bed after surgery. One of those was service bulletins. There are a handful out there for the RV-10 and are a lot like AD’s issued by the FAA, but they are not mandatory by law. Highly recommended, however, so in the home built world, you comply with them. With this being a build log, I wanted to document them here and then I’ll make the associated entries in the air frame log book once I have one.

The empenage kit (oldest original kit) was delivered in October 2005 to the original builder, thus I have only addressed those SB’s relating to the dates affecting our kits.

SB 06-2-3 is for the vertical stabilizer rudder mount. This SB was completed by the original builder and complies with all aspects of the SB. I could not get a good picture inside a tiny access hole, however, visually confirmed the doubler plate is in place inside the main spar of the VS.

SB 06-9-20 is for the trim cable anchor nut on the elevators. While our kit does have the double welded nut, I chose to upgrade to the CNC machined piece by IFLYRV10.com.

SB 08-6-1 is for the F-1010 bulkhead near the vertical stabilizer in the tail cone. My kit came with the SB contents and I completed it as part of the original build of the tail cone.

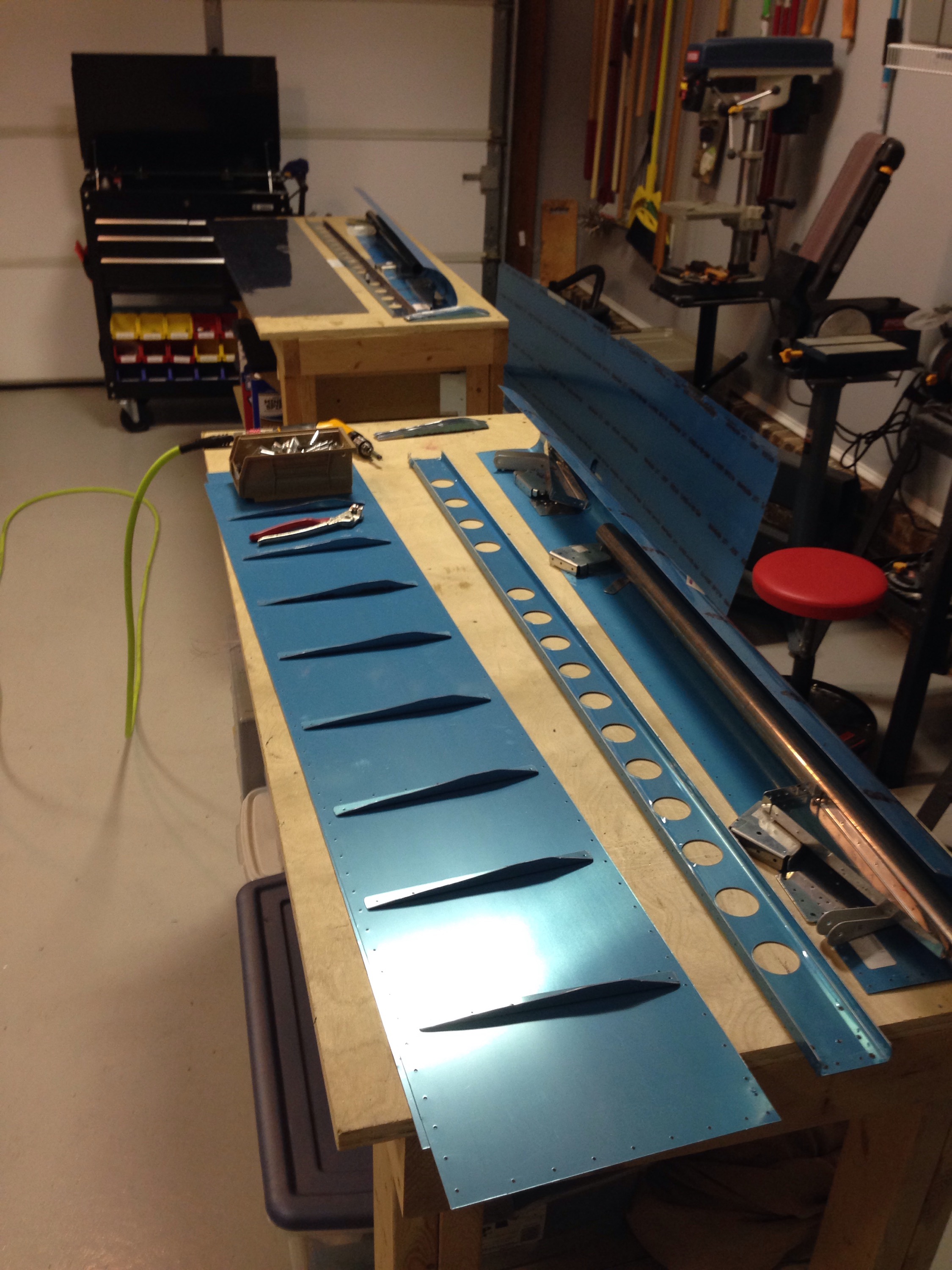

SB 16-03-28 is for the aileron hinge brackets possibly cracking on the inboard aileron mount. I have removed the portion of the gap fairing to allow future inspection and no further action is needed until flying, at which time an annual inspection of the bracket must be made and noted in the log.

There are other SB’s that will affect our build, however, I have not gotten to that stage of the build yet, so will cover it in another post.