…that something off plans you did has already gone very wrong. To be honest, that ton of bricks actually hit me while reading VAF as part of my nightly routine. Another 10 builder posted about his fuel return line fitting interfering with the spar and warning others about this issue. I looked at his pictures and thought to myself, wow, one are just like that. Damnit.

As part of the EFII electronic fuel injection system, a return line needs to be plumbed into each (or one) tank to allow excess fuel to return. I plan on having a duplex valve, so need a return into each tank. The problem is the location I, and others, chose was going to be right in front of the spar, thus not allowing any line and or bolt to be installed. This was going to necessitate removing both tanks and somehow fixing the problem without building new tanks.

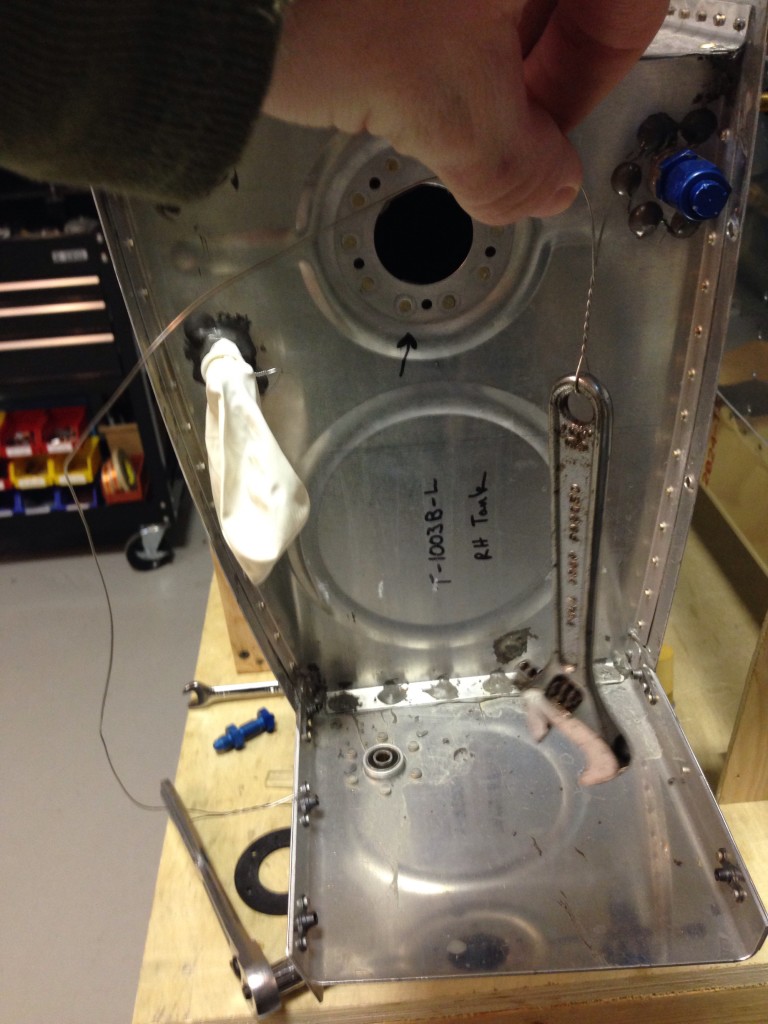

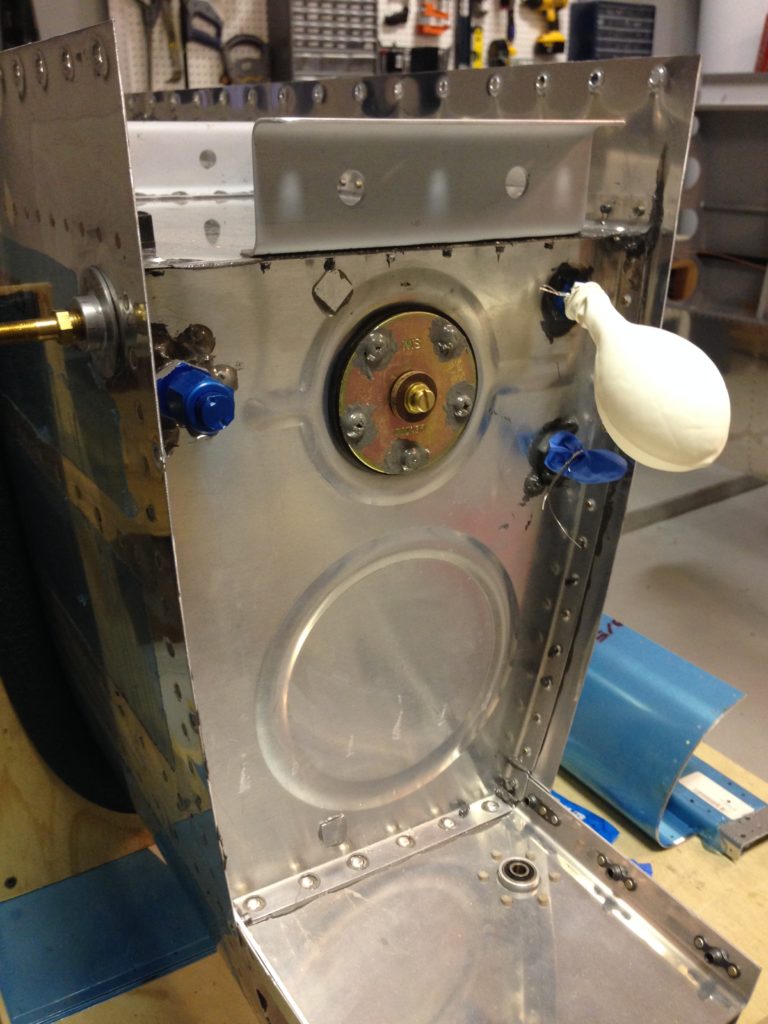

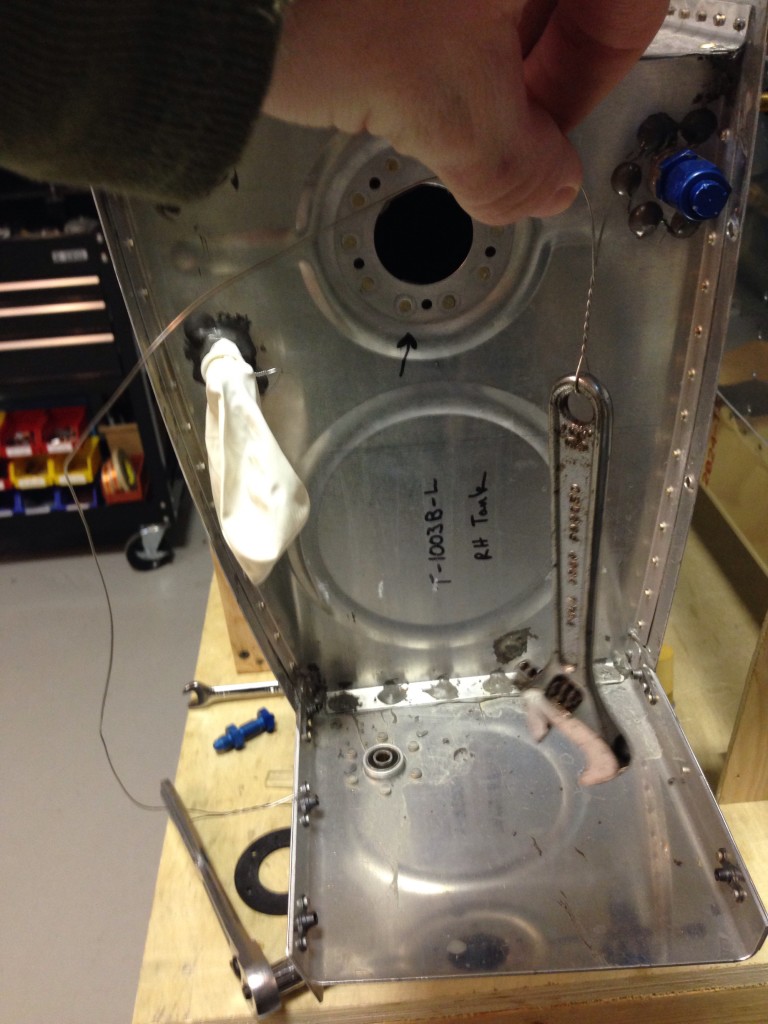

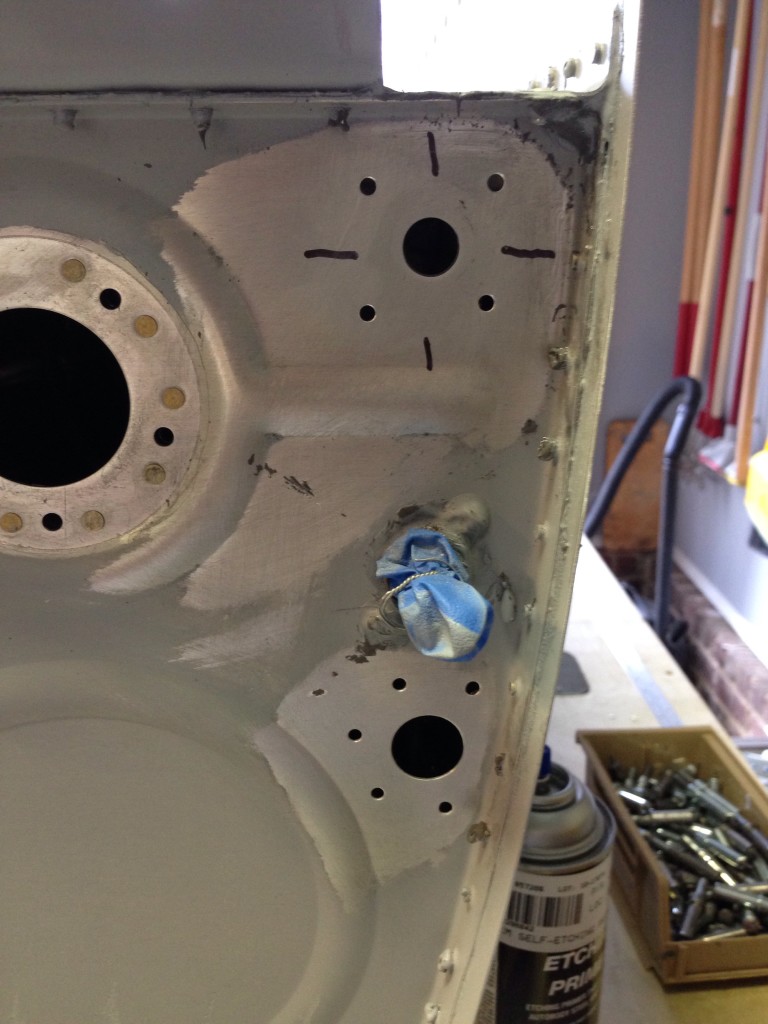

You can see the return line on the left in the very corner. Bad place to be. Some have cut an access hole in the back rib and used a kit from Van’s. But I hated to introduce so much weight and mess if I didn’t have to. I decided after a lot of thought that I could get a wrench inside and remove the fitting without too much trouble.

I put safety wire on the wrench so it would not be lost inside the tank and got to it. With a little patience, I was able to break the tourque and pro seal to get the fitting out.

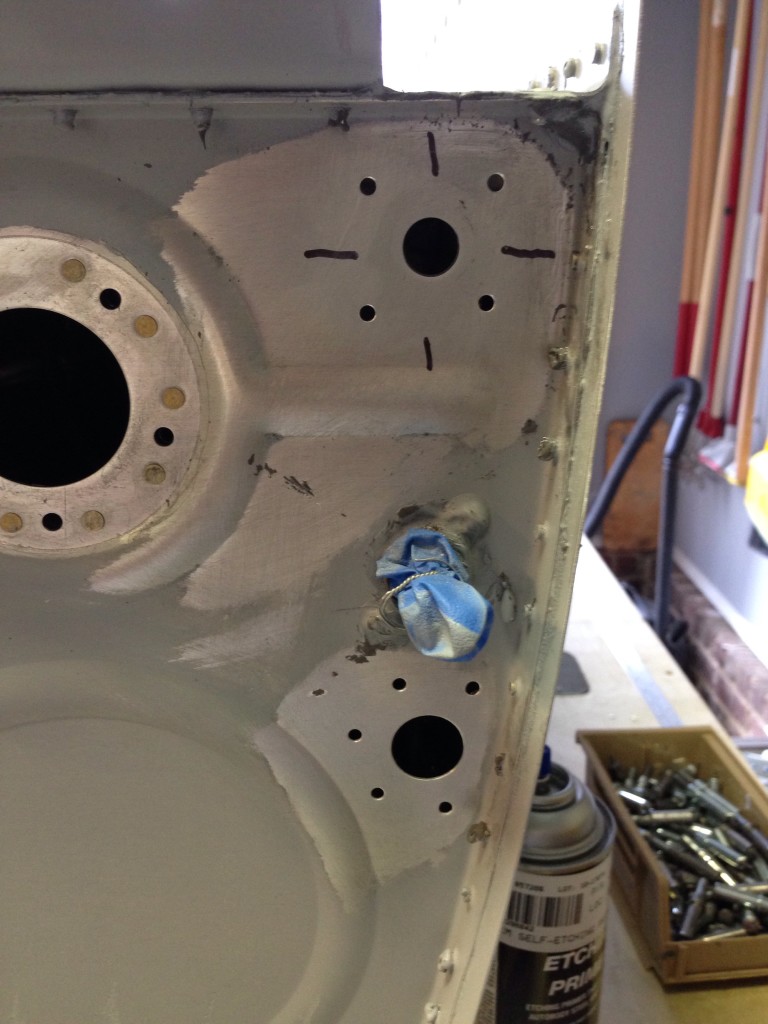

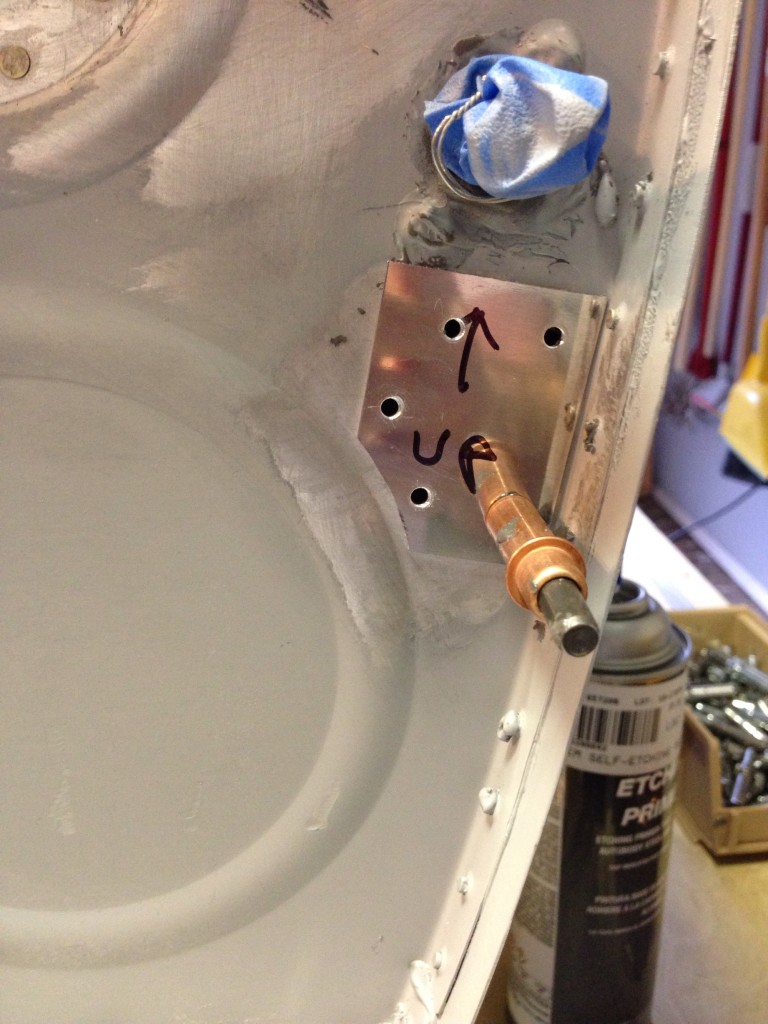

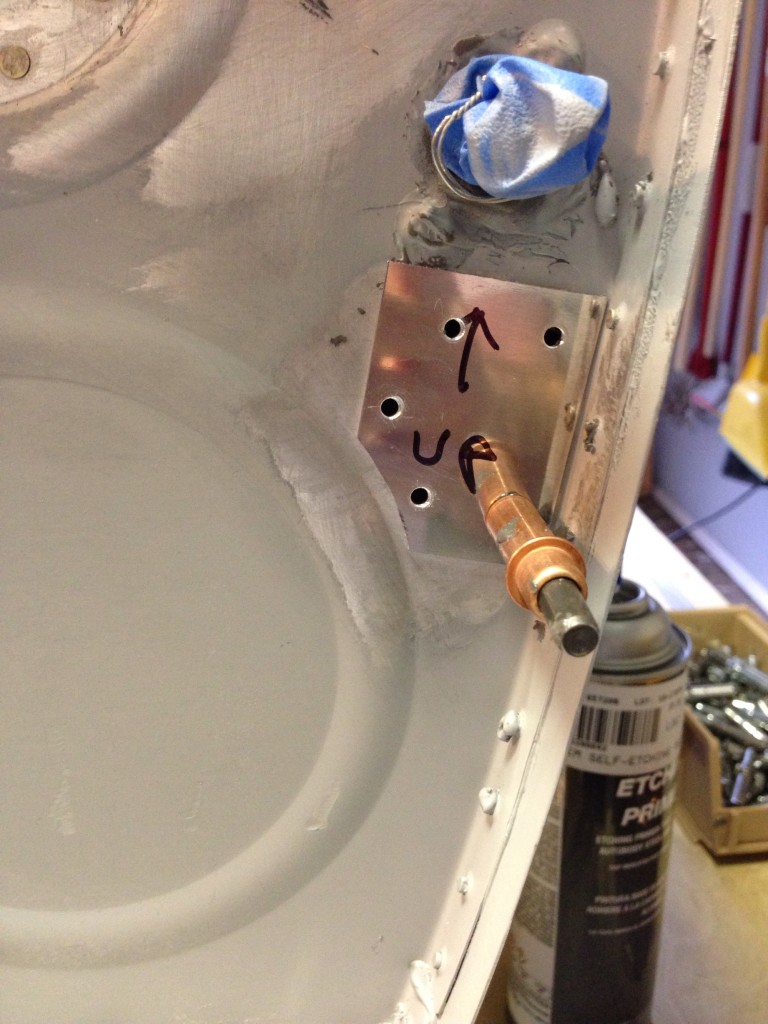

After that, it was just a matter of making a patch for the old hole and properly placing the new hole. Sounds simple, right? Well, let’s take the opportunity to make it better. FEedback from EFII was to have a larger fitting for the return line so I ordered the parts and had a brilliant idea of using a left over fuel bong plate. I thought that would be a nice fitting that I could just screw the fitting into. Wrong again. Different threads. I discovered that after already drilling the holes. So another patch was in order.

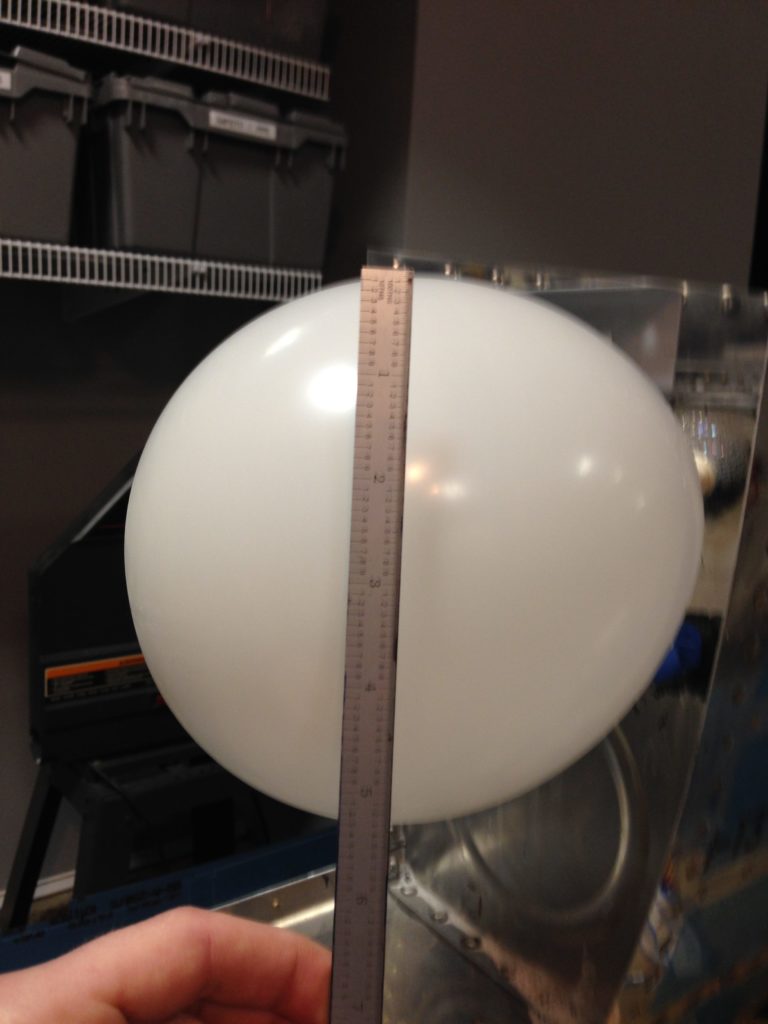

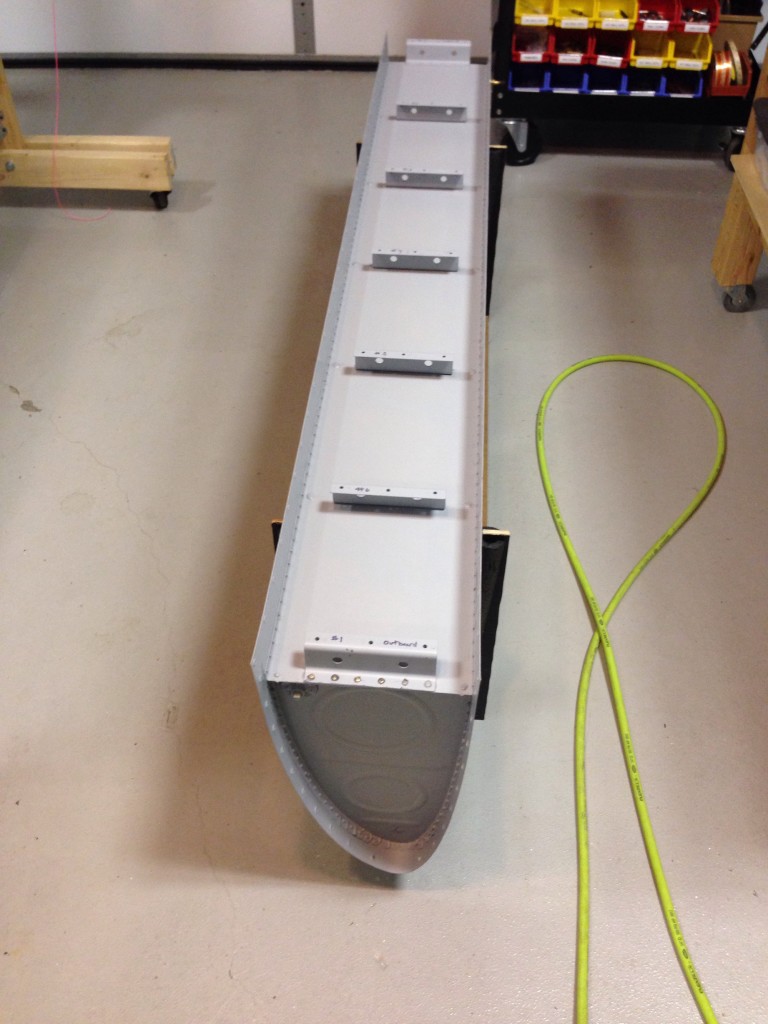

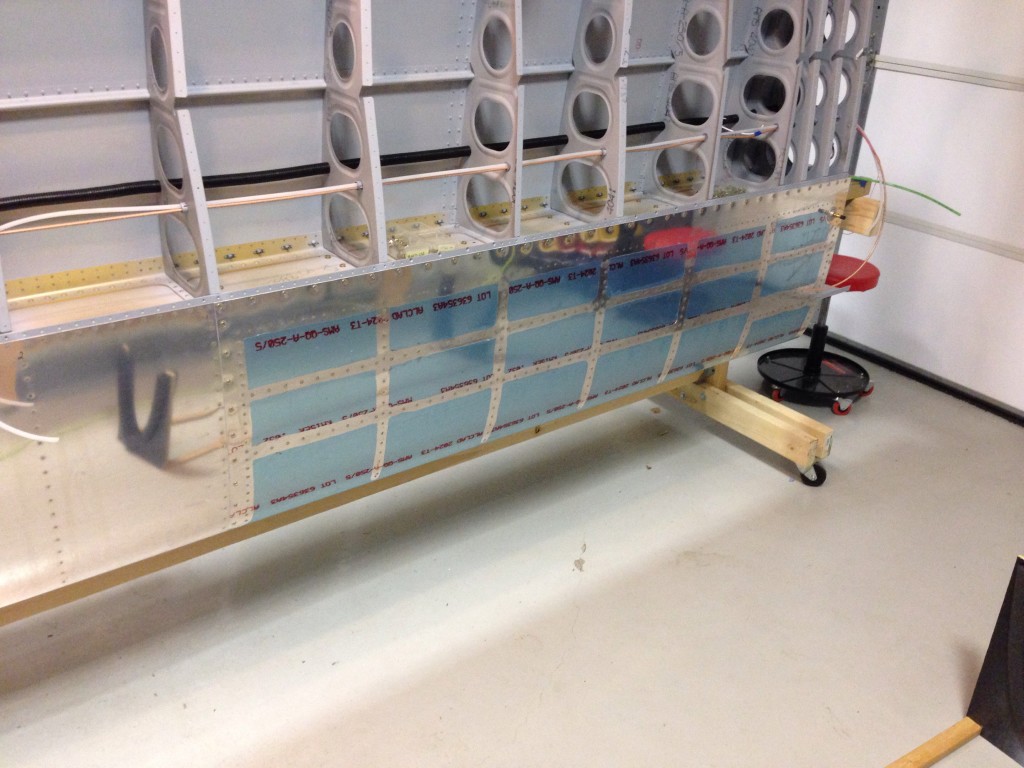

In the end, it was a one evening job and I didn’t have to cut a hole in the tank since I was able to go through the fuel sender hole. Another two day balloon test with no leaks anywhere on the tank reassured me on the construction. Finished priming them and back on the wings they go, hopefully this time for good.