Perhaps the biggest and most expensive decision in building a plane is what engine will be powering the hopes and dreams of the builder while turning many dollars of avgas into adventures. Some may know that I’ve been involved with an alternate engine that has unfortunately not matured enough to be on my plane just yet. I’ll detail that in a future post, but this one is all about the Lycoming!

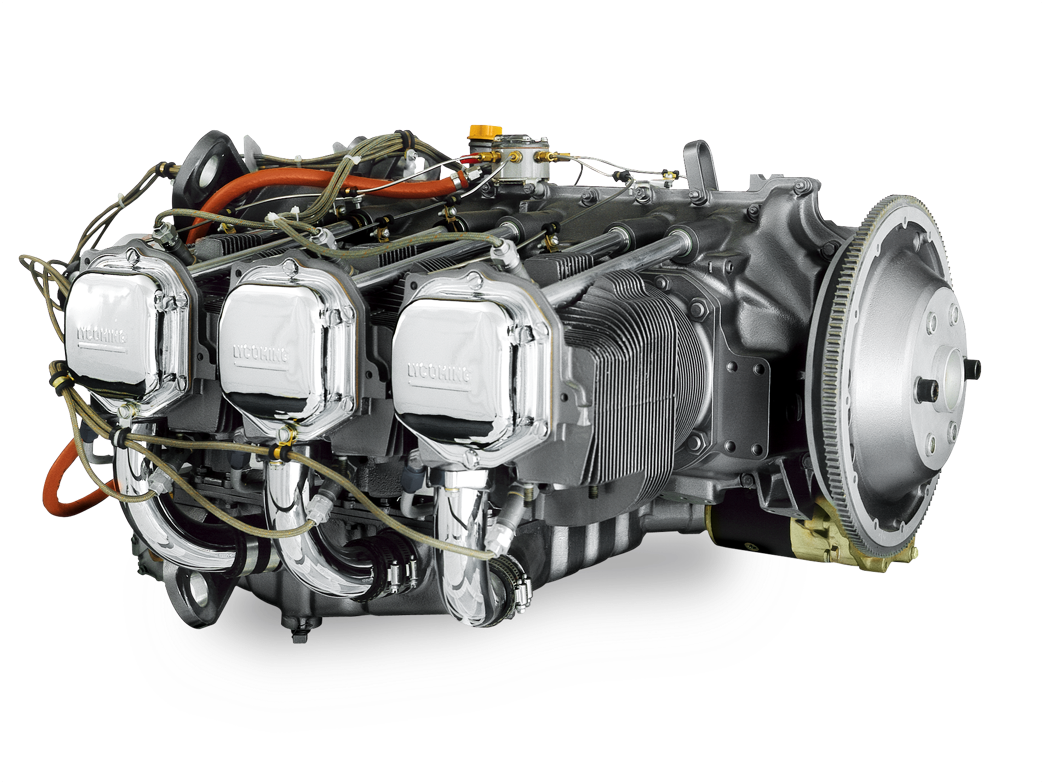

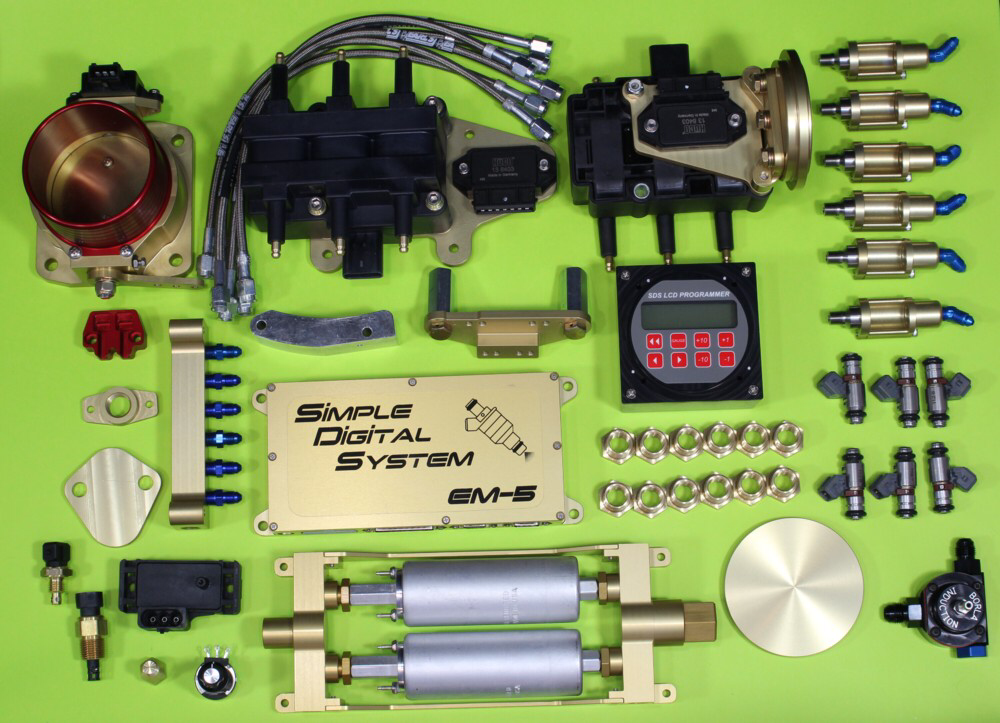

The backstory to what impacted my decisions stems from my flying experience, goals and missions for our plane, and personal preference. I knew that I wanted to start off with a completely new engine, no overhauled components. That is not to say an overhauled or even factory 0 time (but not new) engine isn’t as good as being brand new. I just want a fresh start and a foundation that I could overhaul in the future. I also want an engine that is efficient and powerful. I’m not interested in exceeding Vne or supercharging the thing to 1000 horsepower, but I do want something a little hot rodded above the stock 260 horsepower of an IO-540. I also want it efficient, not only for mission range and cost, but to be somewhat green and environmentally friendly. Afterall, trees need hugs too, right? Most importantly, however, I wanted to have a modern engine or at least as modern as you can with a 1930’s tractor inspired design. That meant electronic gizmos and a lot of them!

While researching new engines, the usual suppliers popped up. Van’s will sell a crate engine with few if no modifications or choices available. Lycoming will sell directly through Thunderbolt lines with some options available and even paint the engine a custom color as long as that color is red! Barret Precision Engines can get a new crate engine or overhaul a used core to build essentially anything you want. Lycon will put 54 to 1 compression pistons that require nuclear fuel to run and charge you the equivalent fee for it. Numerous local shops can build from parts or rebuild a core engine. Or you can simply purchase a running engine from a sellar and slap it on the plane. For me, it came down to two vendors, Barret and Aero Sport Power.

Aero Sport Power is in Kamloops, BC and has been building experimental and certified engines for decades. They have a great reputation with the aerobatic folks and have an entire business division to cater soley towards ameature built aircraft engines. They also have a unique offering, a build school that is a three day course where you get to participate as much or little as desired in the build of your engine capped off with a first start and test run on their test stand. Darren is a phenominal resource and will hand walk you through everything from figuring out which engine you actually need (IO-540-R2D2 hah!) all the way to which hotel is best to stay at in BC and how to run your new engine during the first few flights. What I liked about Aero Sport the most is technical: they are an authorized Lycoming builder that can order a new engine kit unassembled. What that means is they build the engine to my specs, not take a crate engine and rip components off to replace with aftermarket upgrades.

So I called Darren and started talking about what I wanted. Lycoming 540 with 9:1 compression, SDS dual ECU injection and ignition, BPE cold air induction, no mechanical fuel pump (not needed with SDS) dual groove flywheel for aircon, remote oil filter, 70 amp alternator with 30 amp back up, and of course custom paint scheme. This all was an easy kill for Aero Sport who promptly gave me a quote and lead time. They then put up with me asking questions, requesting information, putting the purchase off, and finally committing in January of this year with a July build date. The price wasn’t the cheapest, but it also wasn’t the most expensive, apples to apples. They were, though, the only shop who could build (not re-build) the exact engine I wanted. The icing on the cake was the chance to come up and help build it! This is how excited I was!

With the deposit paid, planning began on keeping the copilot happy by having a vacation in conjunction with the build class. We worked out flying into Calgary and taking our time traveling west over the mountains to Banff then to Kamloops before spending a few days backpack camping back in Yoho then flying home. To top it off, my dad and step mom had a similar idea, taking a cross country train from Toronto to Vancouver then meeting us in Kamloops so pops and I could build the engine father/son. I won’t get into all of the vacation details, but we now have free tickets from American thanks to our luggage traveling halfway around the country before making it to our hands on day three of the trip. We traded the backpack camping for day hiking and an Air BnB with a hot tub due to snow and head colds and came home happy!

The summary for builders is take a lot of time and research the build shop you want. Build the engine like you build your plane, just the way you want it. Need to save money? Do it. Want the bling? Chrome everything. More power? Do it. Your life and the lives of your passengers depend on your powerplant more than any other component so make sure you are comfortable with your engine and are happy with your decision. I’d be happy to talk with anyone about the finances and other small decisions to help a fellow builder.

Stay tuned for the build school write up.