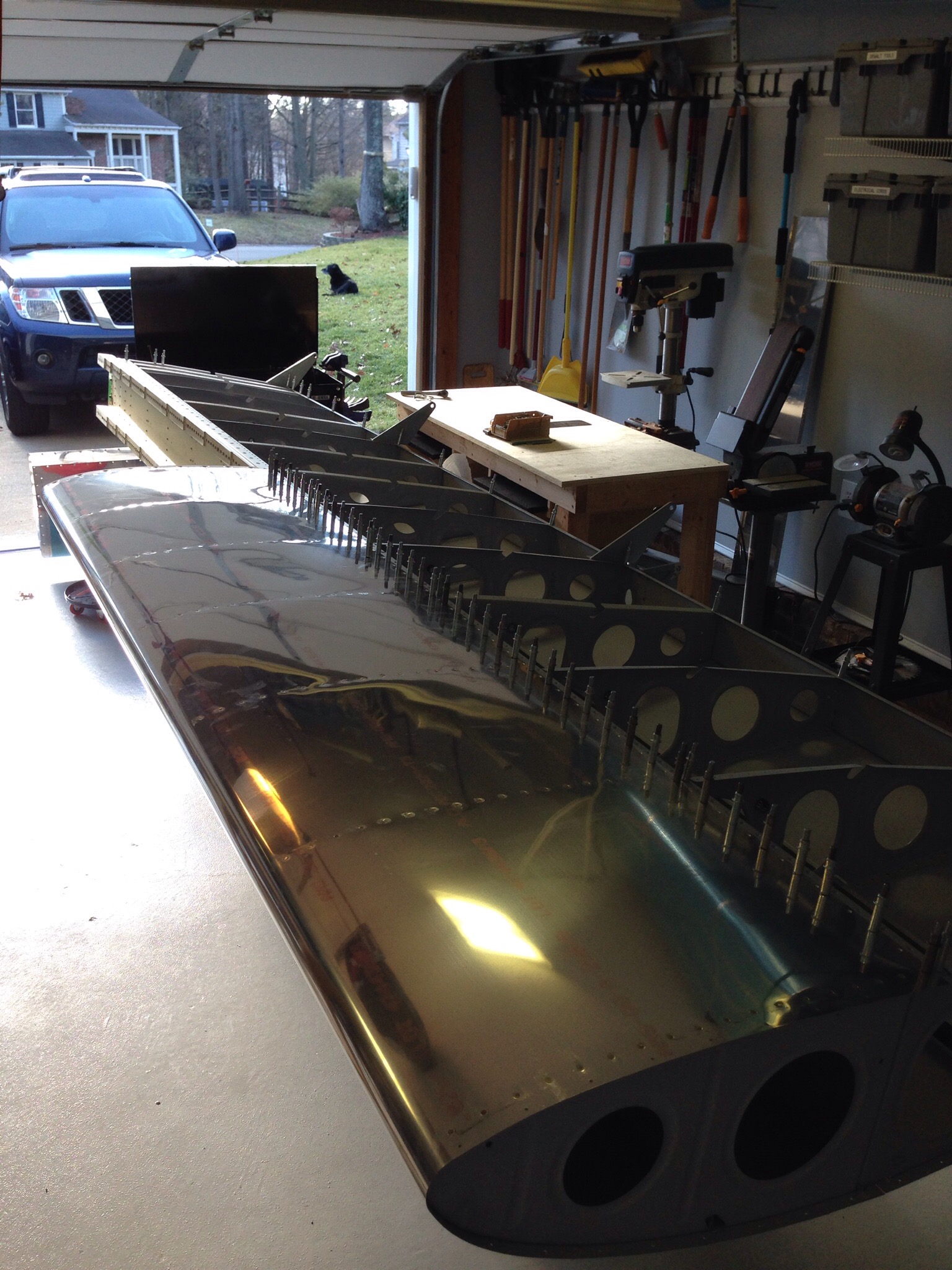

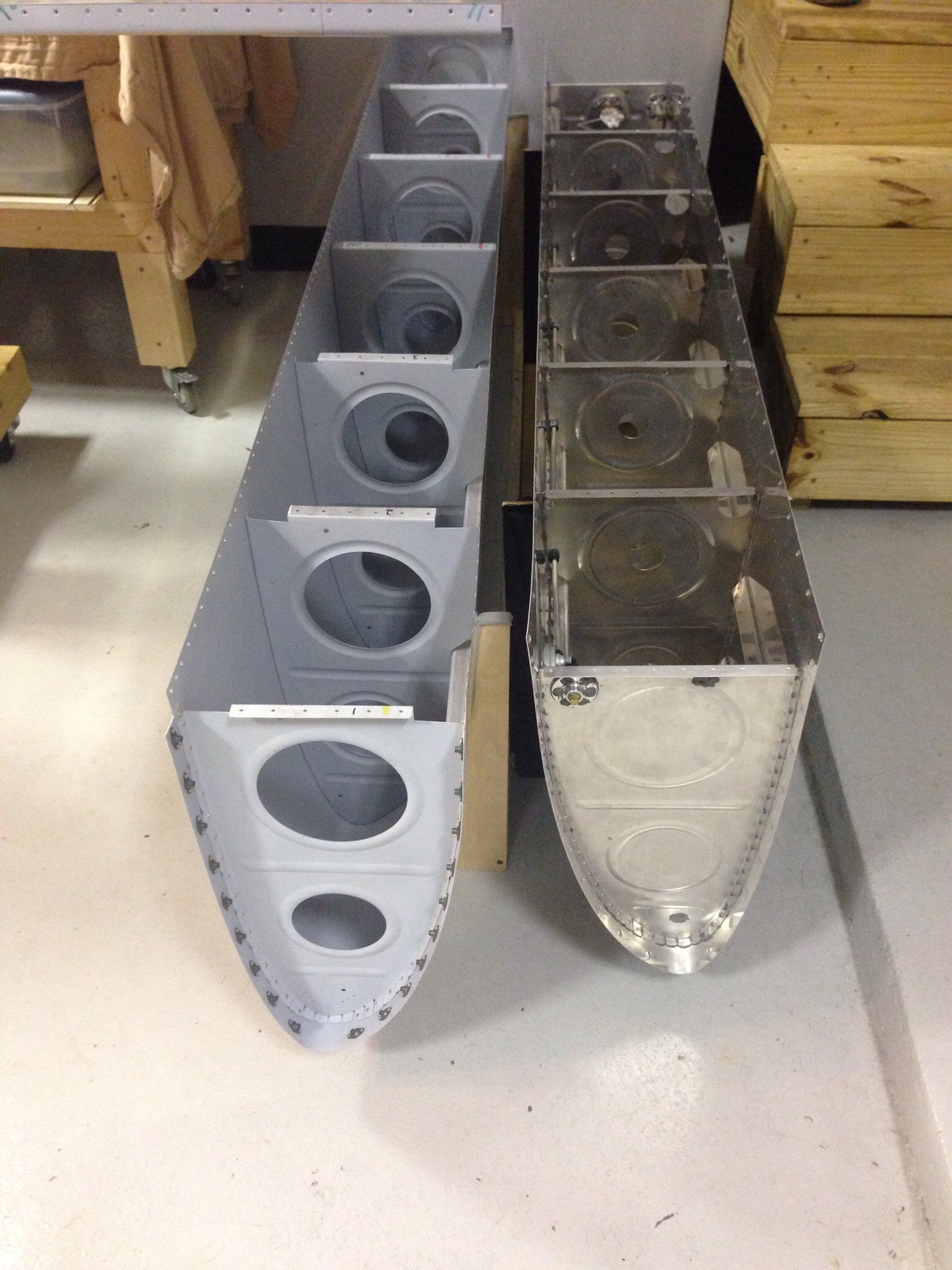

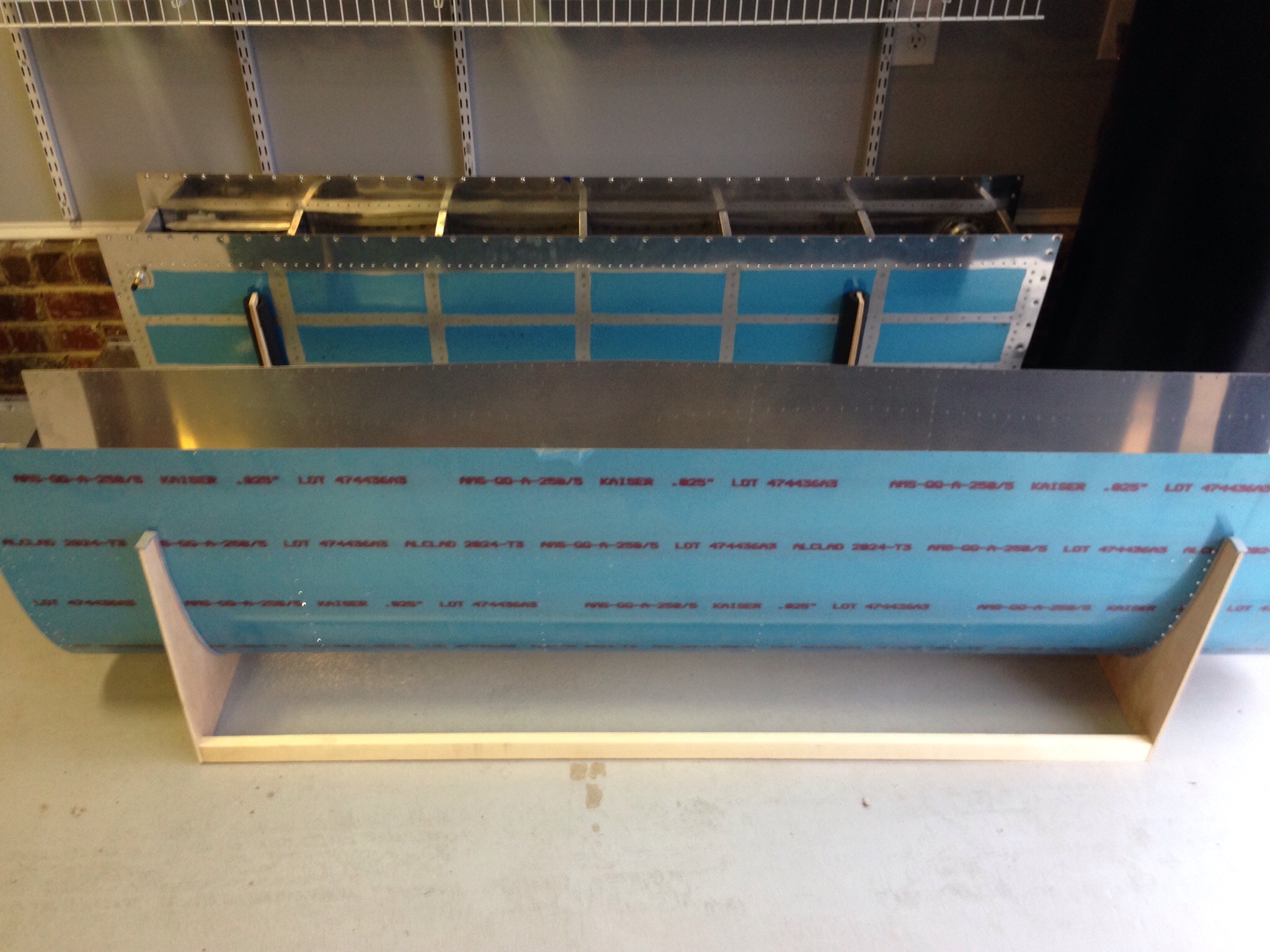

With the recent success of the fuel tanks boosting my spirit, I got to work over a long weekend on the wing and leading edge union. It’s a big step, as it adds a lot of surface area and shape to the wing. It also now takes on the appearance of a wing so hopefully folks can tell what the heck is hanging from some wooden rack in my garage!

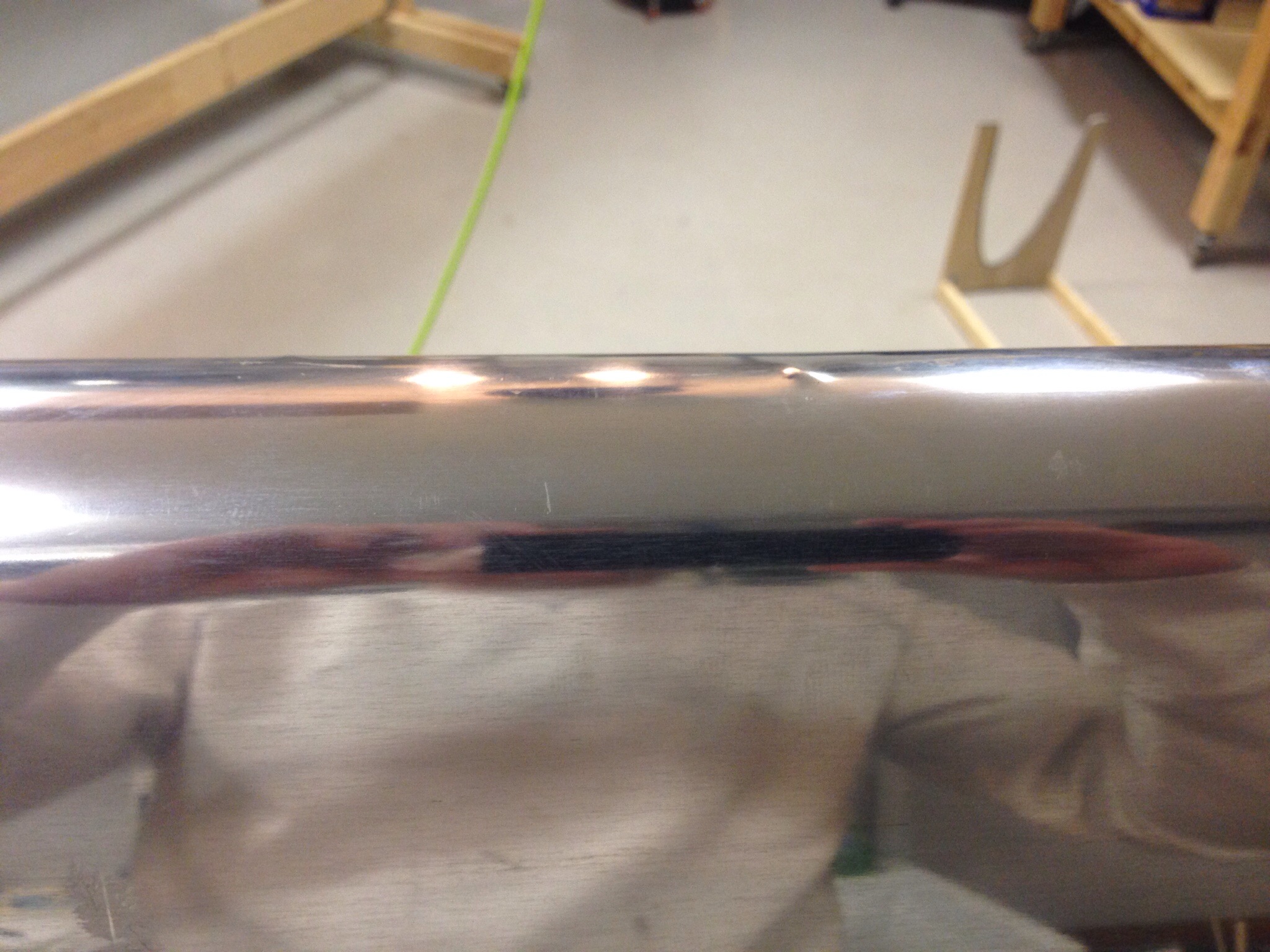

I started solo by clecoing the leading edge to the right wing spar. Working on the bottom first, when I got to the top side of the wing (it’s laying upside down) I noticed that the skins overlapped instead of a nice butt joint. Thus, I removed all those clecos and started from the top side (again on the bottom as it’s upside down) first to get the joint smooth.

It worked like a charm and within no time, I was using my squeezer to rivet the bottom of the skin to the spar. This is when a tool like this comes in handy, as it makes quick work and nice consistent results.

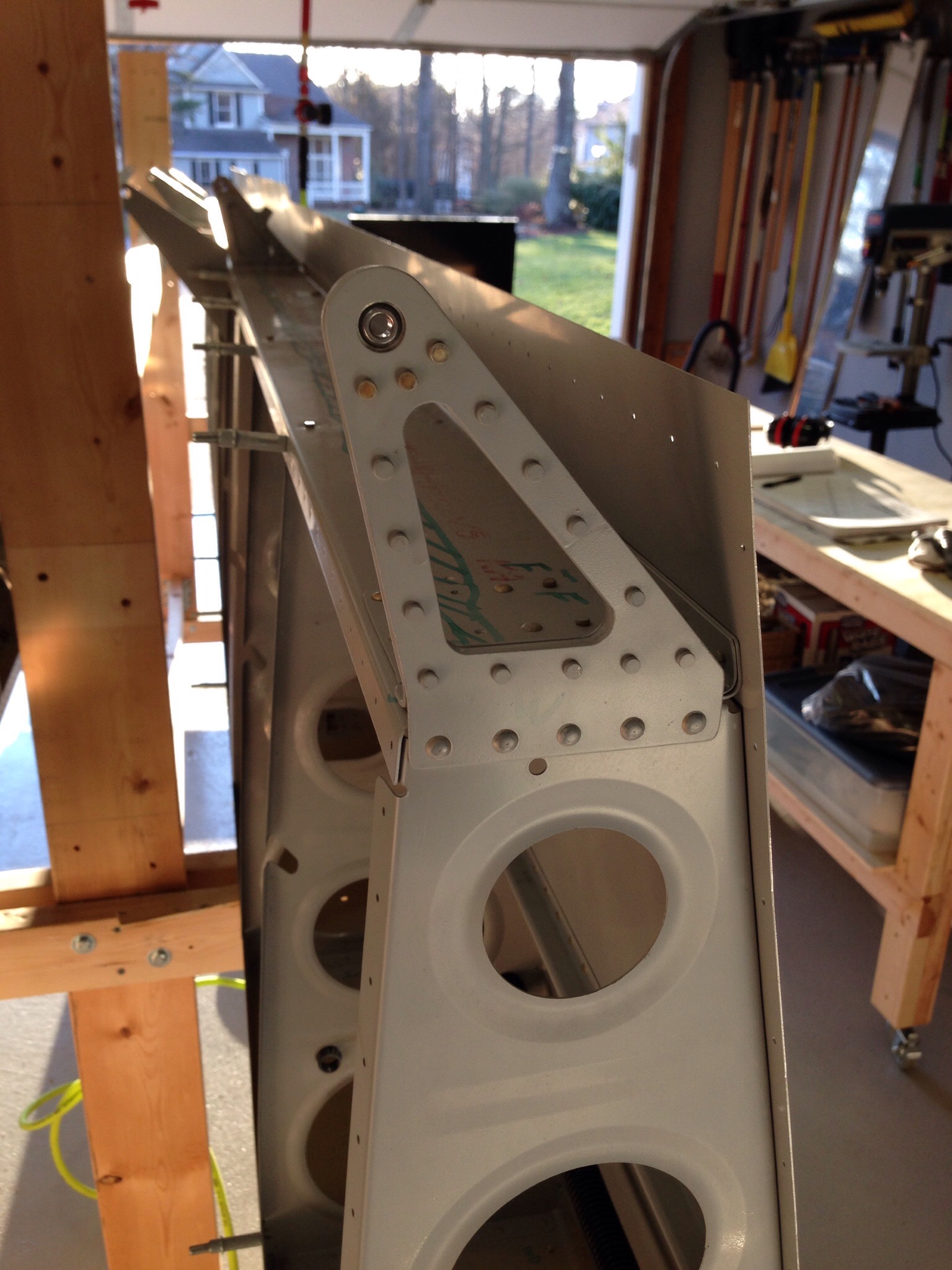

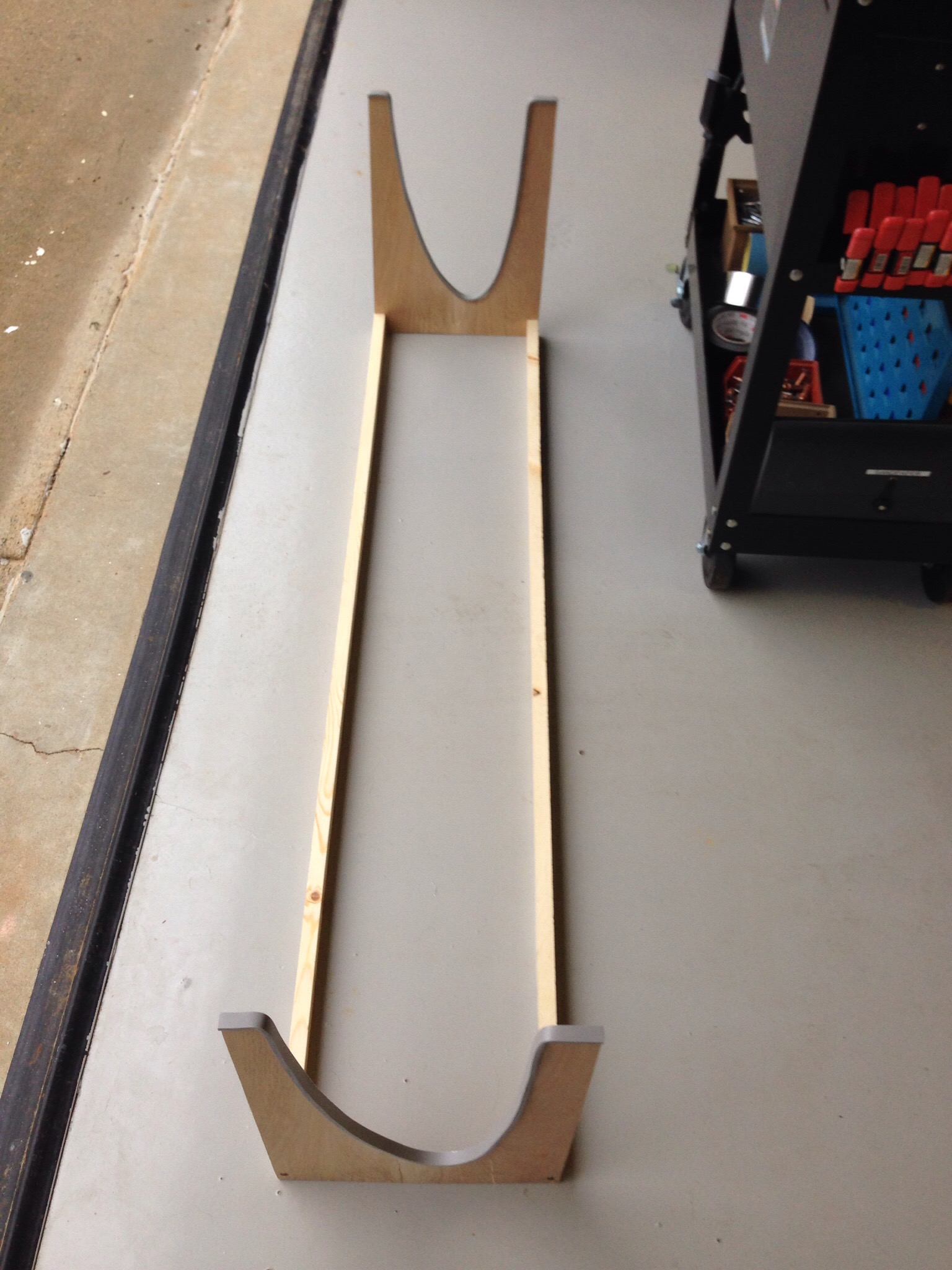

Then it was time to figure out how to position the wing so that two of us could rivet the top skin. It worked out for me to use the DRDT2 dimpler as a spar stand and the wooden cradle on the other end. I put a couple of pieces of wood to block it and it provided a very stable stand for the wife and I to team up for some riveting.

We made great progress, finishing both leading edges, the rib/spar rivets, and moving on to modifying the wing rack for the final time. With the leading edges on the spar, I had to move to the carpet tactic to form a soft cradle for the leading edge. We had the material and it was a quick fix. Hopefully the last time we’ll need to reconfigure it.

I used the good weather to swap the wings from side to side on the rack and finish priming the interior of the left wing. The last project of the day was to blow out both tanks very well and ensure no foreign contaminants were left in them before sealing them up as the next task.