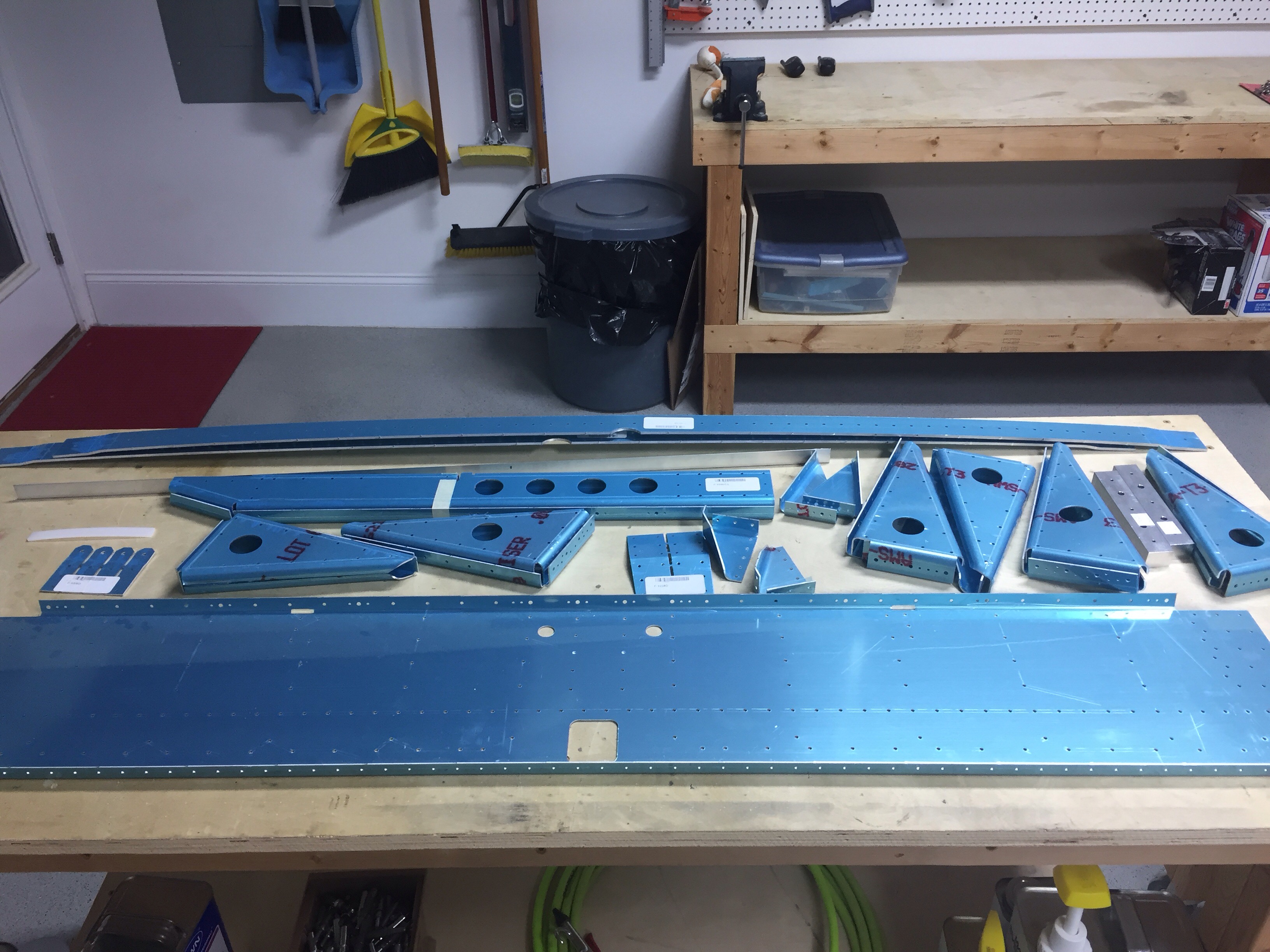

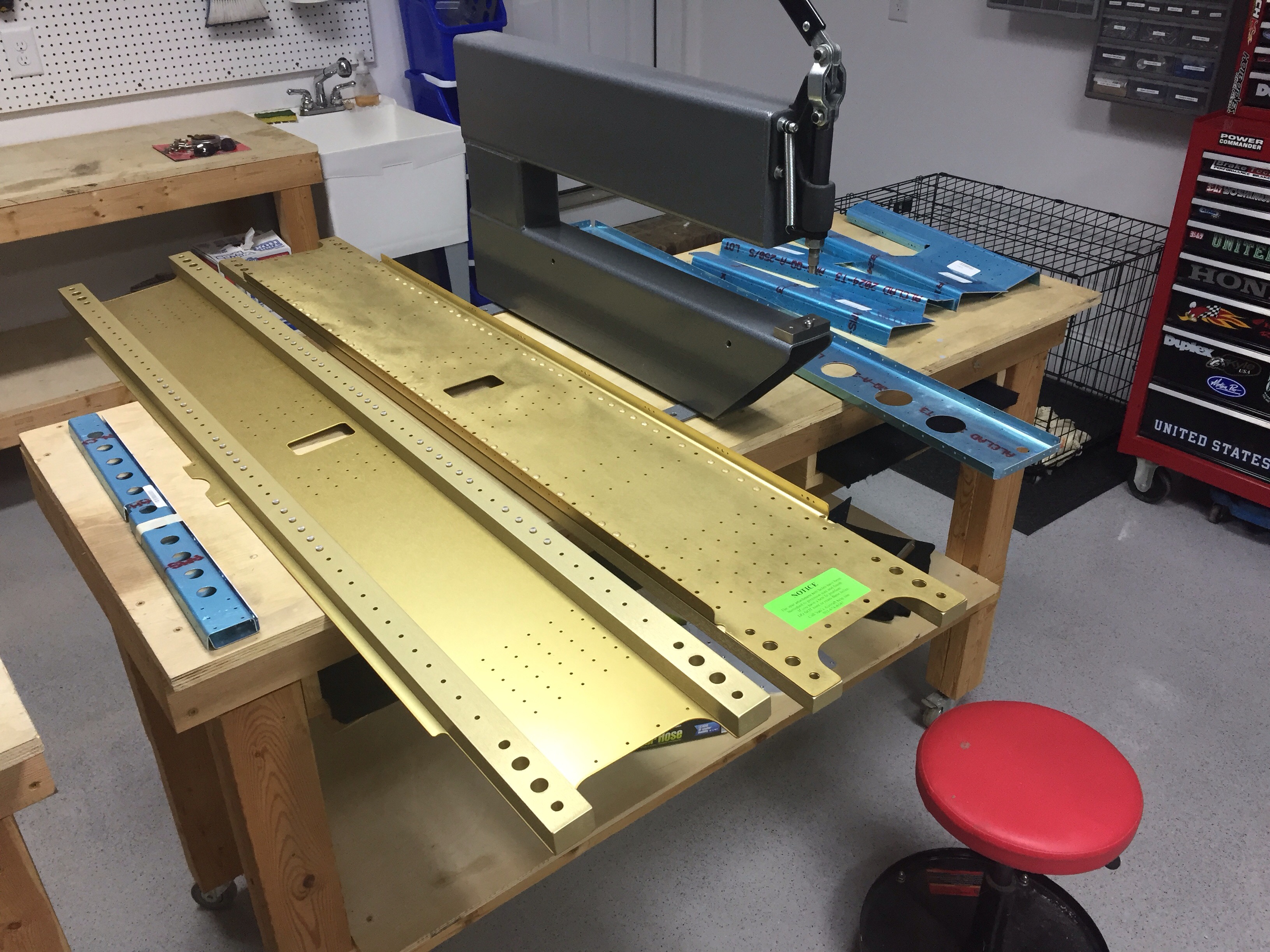

With the decision to hold off on the bottom wing skins until after another EAA tech counselor visit, it’s time to move onto the fuselage kit. This kit arrived to our old house over a year ago, and has since been stored on the overhead racks in the garage. The first challenge was to find all the associated parts that resulted in lots of trips up and down the ladder. Alas, I finally located everything and was able to get started on the spars and seat rails.

I’m already seeing a lot of smaller pieces but many more than in the wings, and of course beefier substructure as it carries most of the loads of the aircraft. After the normal routine, I got to riveting and quickly remembered it’s been a year and a half since I’ve bucked a rivet. It has also been a year and a half since I’ve drilled out a rivet. I can now say I’m current on both tasks.

The front spar is all ready to go with the aft spar and assemblies up next. I’m also happy to say that for the past three weeks, I’ve worked on the airplane every single day, whether it’s physically in the shop or electrical planning. Not only am I really feeling motivated by that, but I’m also making a lot of progress.