After a several day weather delay, Vic arrived on a clear sunny morning, November 13 2019, in his RV-10. Vic had given me some homework to accomplish before he arrived and I had all of it plus extra paperwork all prepared in the hangar. I used the EAA kit to register the aircraft and was thankful for the guidance with the paperwork, as it doesn’t always make perfect sense. He also requested certain panels removed and let me know what could stay assembled pending anything noticed during the inspection.

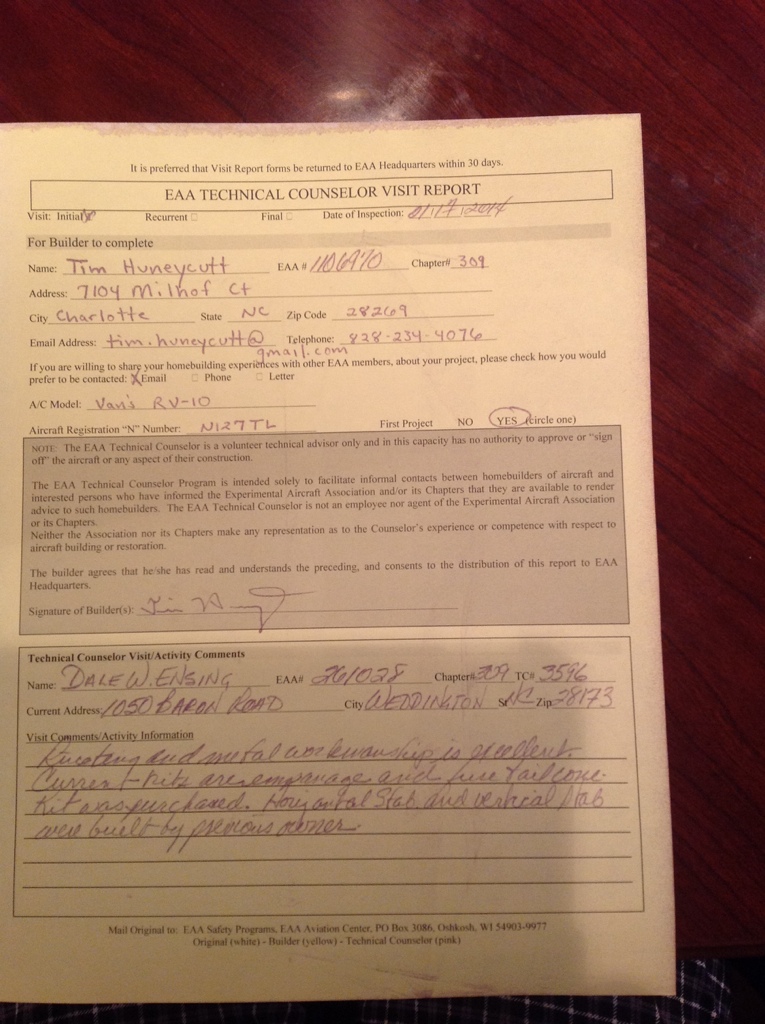

First, we sat down and did the paperwork. There’s quite a bit but he’s got a great program and process to accomplish it all in an orderly fashion. Everything was in order and I had my first logbook entry for him to review. I also had my build log website ready for him to look at, but learned he had been following along already (even though it wasn’t updated completely).

After the paperwork was done, we started a thorough walk through of the plane. He certain has his hot spots to look for and went straight to them. I think since he was able to follow along with my build and see my progress, it helped speed up the inspection. My work looked really nice to him as we went through the wings and even got a compliment on my riveting! While he does a great inspection, he also relies on the builder to do fundamental testing. We didn’t do a control surface check with the digital level nor an engine start which I thought would be required, but he did check it all over with a fine toothed comb.

My proudest moment was when he told my dad later in the morning that “No kidding, it is the cleanest install that I have ever seen.” Now, I’m sure he tells all the builders that, just like the doctors tell dads that their kid is the best! But I still appreciated such a flattering comment from the King Vic!

Of course, he can’t sign off everything without finding a few things! I had some wires still needing a few more zip ties just to prevent chafing. He also suggested a few tips for the rudder trim which I’ll upgrade in the future. The biggest issue was my data plate. I had heard horror stories of failing the inspection only because the builder’s name was incorrect. I made sure to follow the directions to a tee in the EAA guide. Unfortunately, I took for granted that Last Name (comma) First Name equals First Name Last Name. On the forms, it tells you to put Huneycutt, Tim S. So that’s what I did thinking they know Tim is my first name. On my data plate, it said Tim S Huneycutt. Wrong. Registration says Huneycutt, Tim S so that’s what the data plate has to say.

Fortunately, Vic saved the day after he ruined it (kidding, Vic) by whipping out a blank data plate and letting me hand engrave it with the correct verbiage. I immediately ordered a new one with professional engraving that I’ll put on after paint.

So yeah, time for the obligatory handshake photo! I pulled Tess out of the hangar and put her nose to nose with a veteran RV-10 for a photo opp. Squinting into the sun, Vic handed over my airworthiness certificate and our 6 year long build project just became a real airplane!