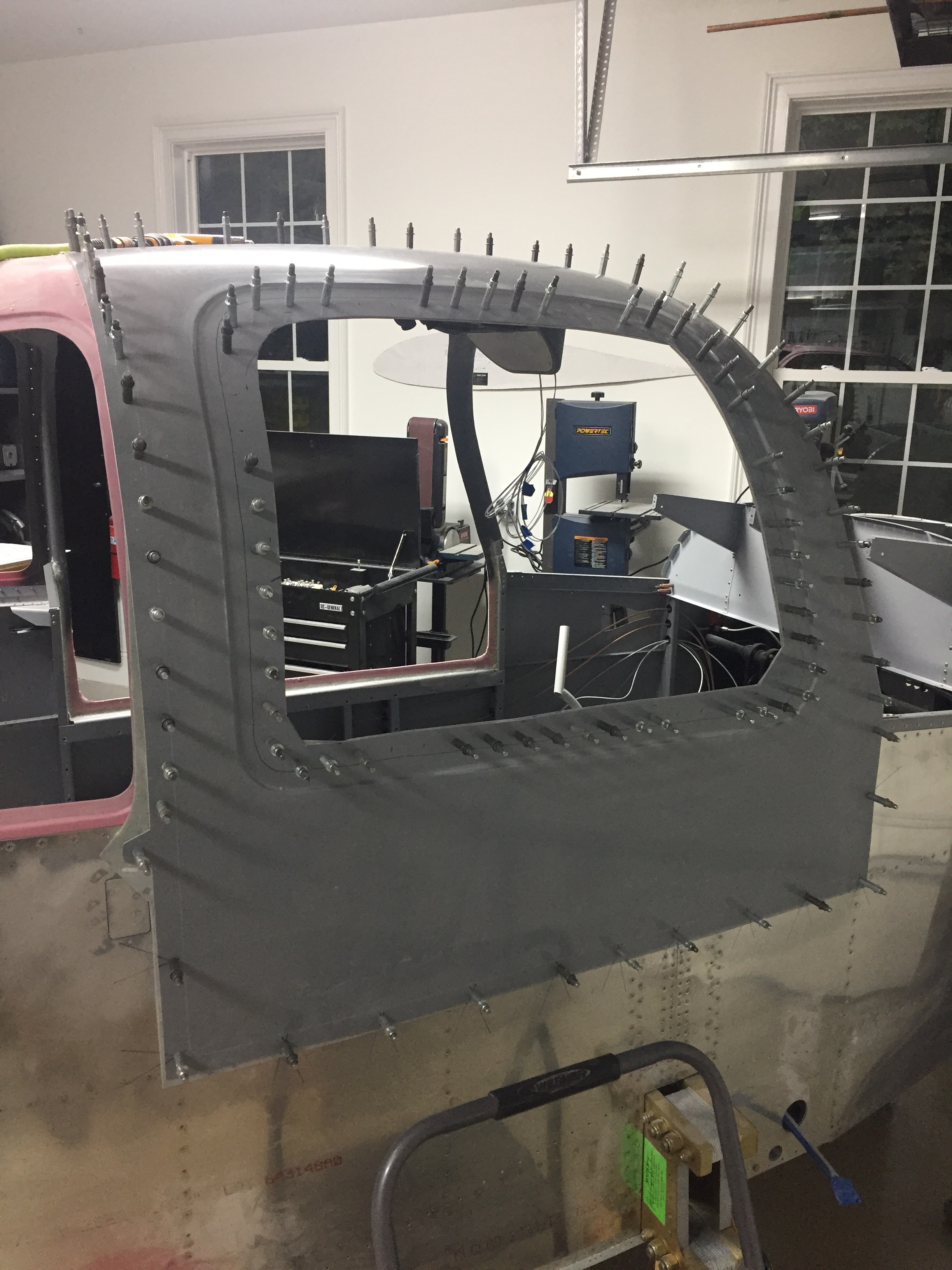

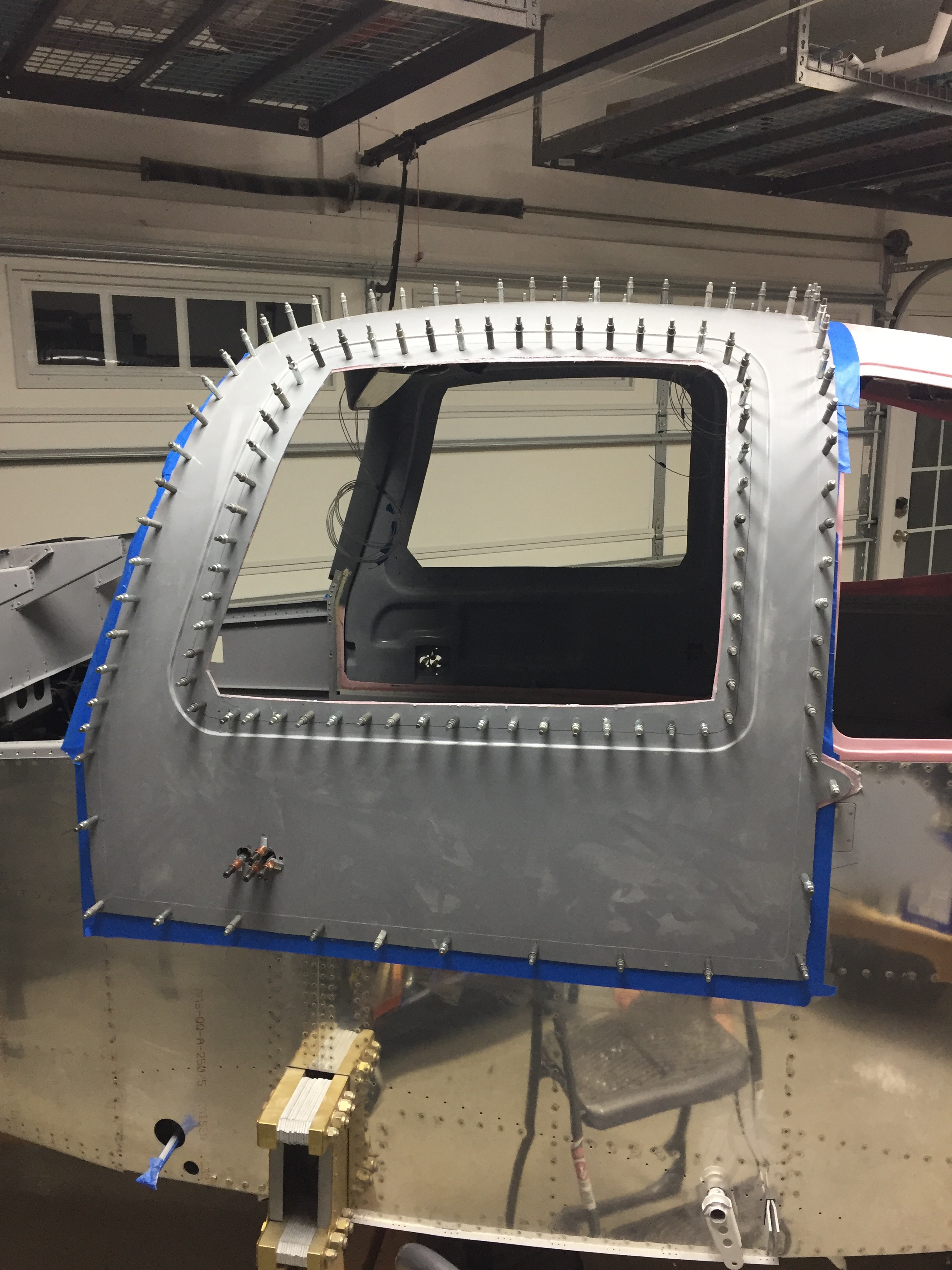

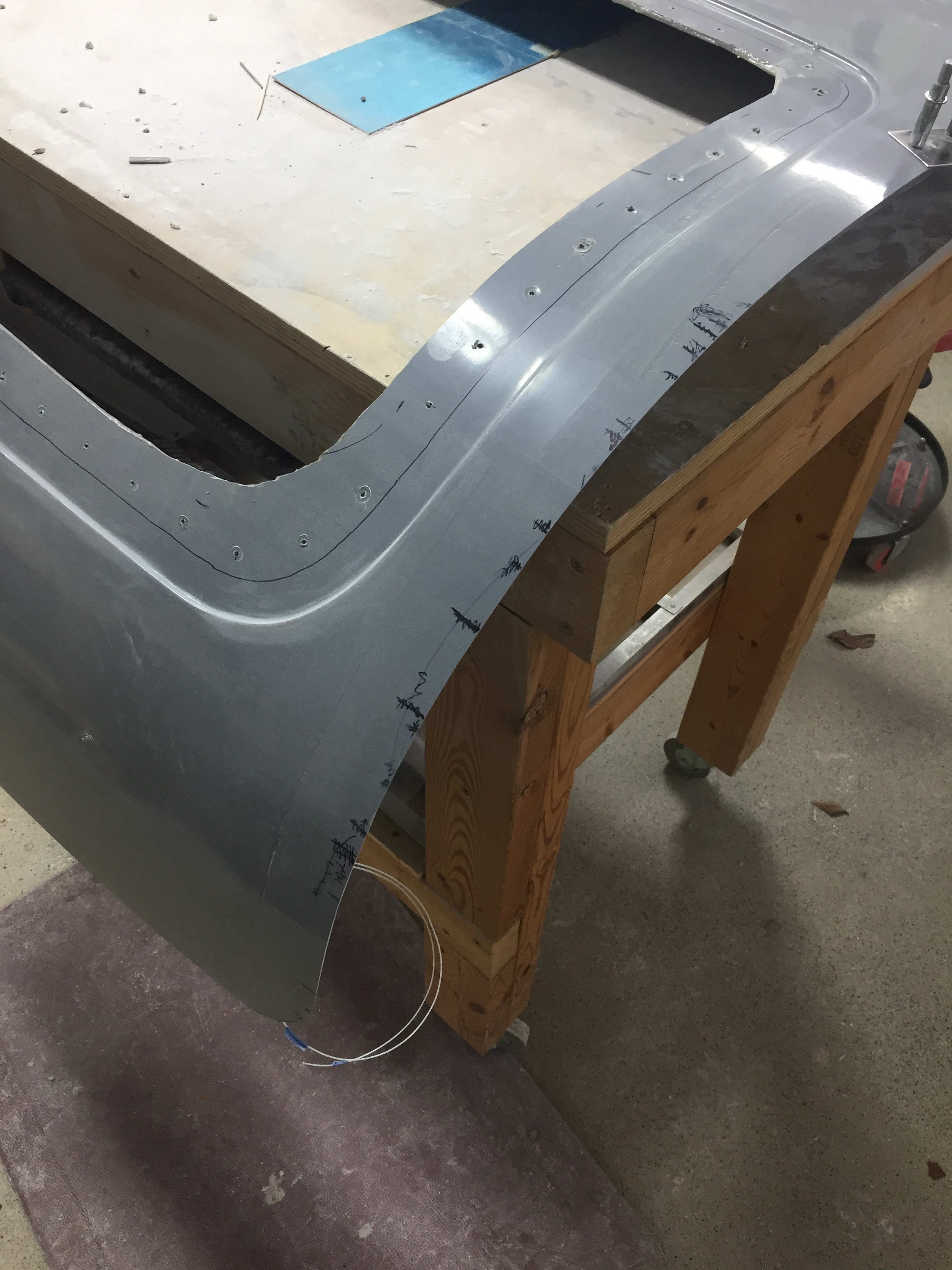

The epoxy dryed overnight and the next morning I was ready to start cursing clecos as I pulled them out of the cured doors. A few were kinda tough and I ruined some clecos, but eventually all of them were out and I was left with two doors!. The next step is trimming the outer flanges to fit flush inside the cabin top and fuselage. It’s a tedious task as you really need to trim them to fit but they need to fit to see where they need to be trimmed. I took a tip from another builder and created a template to cleco on the door and fuselage instead of leaving tabs on the door flange itself per the plans. This allows the door to slide into the frame but ensures it’s held in the same place when test fitting it.

Slow and steady wins the race here, with a lot of sanding/grinding/fitting/repeat to get it just right. I am neither slow nor steady. So after about 15 times of test fitting and removing, I went to town with the die grinder and poof, too much gone. Cardinal sin of building a RV10 door. When all the dust settled, I realized that the doors themselves weren’t too small but I just didn’t take my time to fit them. My scribe lines from the factory were WAY off and oversized. I was shocked at how much material I had to remove to get the doors to sit flush.

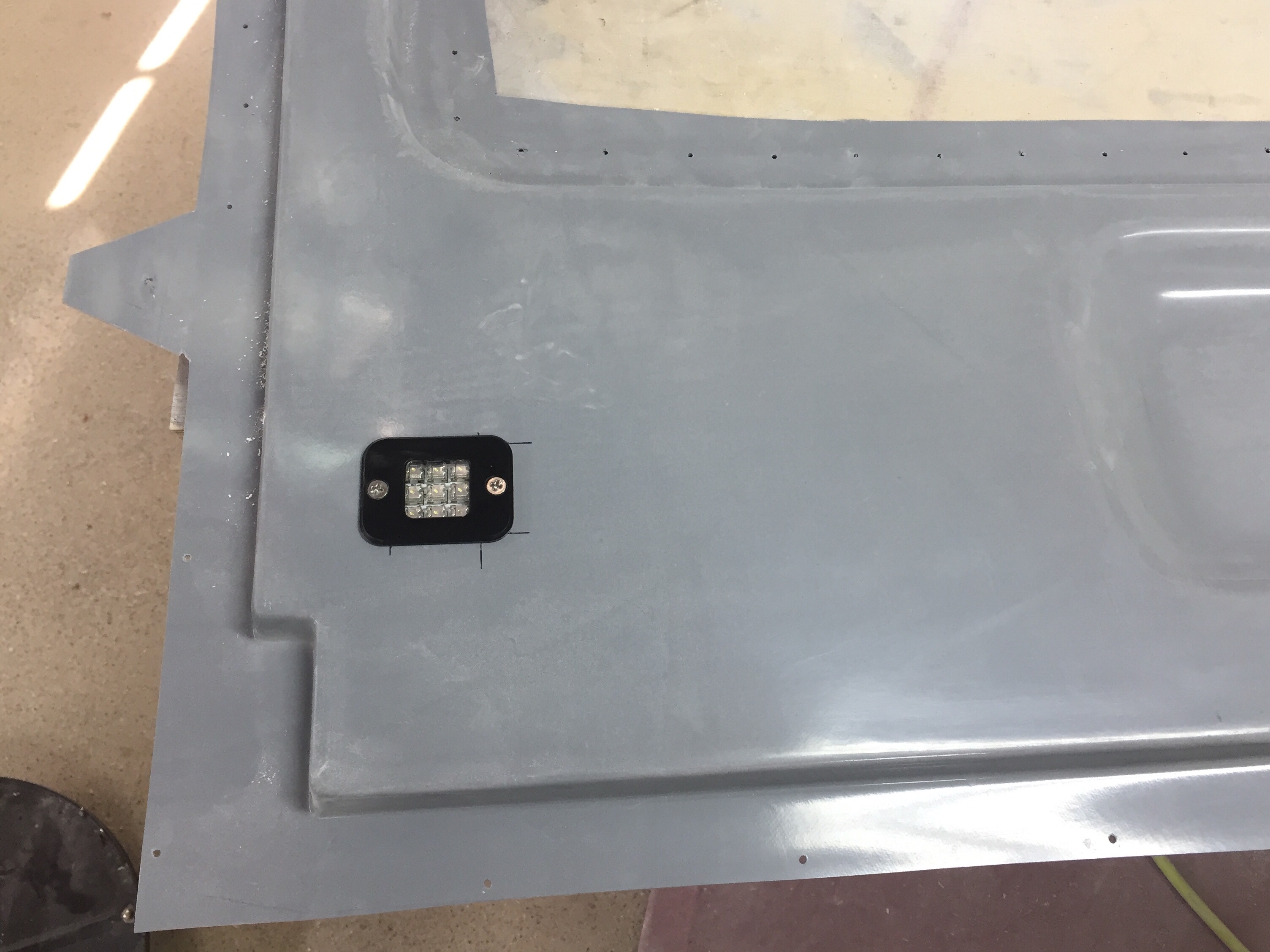

In the end, I put a chamfer on the cabin top and the door flanges to get a nice fit that was a complete waste of time. Since I’m using the McMaster Carr seal, I don’t need a beveled edge on the door and frame and will need to build the cabin top / door up in several places anyway to make the two surfaces flush. Oh well, I knew doors would be a pain so par for the course. Nothing was too bad that can’t be fixed, so I still looked at it as a success.

Once I calmed down, I got to work on the right side hinges which went on quickly and easily. Wouldn’t you know it, I was ready to open the door for my lovely wife to get in her side of the airplane. Except she wasn’t there and there’s no seat and it’s really dusty and I don’t want her touching anything yet since it’s not finished anyway…..